Self-Generation

Incentive Program

Self-Generation

Incentive Program

HANDBOOK

Provides financial incentives for installing

clean, efficient, on-site distributed

generation

August 1, 2023

V.3

1

What’s New Self-Generation Incentive Program (SGIP)

The 2023 V3 Handbook has been updated to reflect the following changes:

• Structural Modifications

o Revised layout of Handbook for easier navigation

o Deleted redundant and outdated footnotes and Regulatory Background

o Updated web links and improved accessibility of hyperlinks

• Language Changes

o Adjusted language for consistency

o Language correction for Capacity Equations (§ 6.4.1, § 6.4.2)

o Revised date for Legacy Residential Projects (§ 6.2.5)

• Proposed Language Additions

o Clarification regarding Budget Allocations (§ 1.1)

o Clarification of the Lottery Procedure in Final Budget Step (§ 2.1.1.1.3)

o New footnote about Heat-Pump Water Heater Program (§ 1.2)

o Clarification on Data Requirements Thermal Energy Storage Systems (§ 2.1.1.3,

Appendix G)

o Clarification on renter eligibility (§3.1)

o Clarification of Developer eligibility (§3.6)

o Two additional participant chapters (§3.7, §3.8)

o Additional language on Resiliency Adder (§4.1.1)

o New sub-chapter on the Generation Budget (§4.1.3)

o Additional language on SGIP eligible equipment (§5)

o Clarification on interconnection requirements (§5)

o Additional language on system sizing without peak demand information (§ 6.3)

o Additional language on Rated and Energy Capacity Calculations for HVAC-integrated S-

TES Systems (§ 6.4.1, § 6.4.2, § 8.1, Appendix H)

o Additional language on Proof of Critical Facility (§8.1)

o Clarification on Authority Having Jurisdiction (AHJ) Stamp Requirements on AHJ

Approved Grid Island Capable Plans (AAGICP) (§ 8.3)

• Additions and Clarifications in the Glossary

o Added Large Thermal Energy Storage (L-TES)

o Clarification on existing terms

2

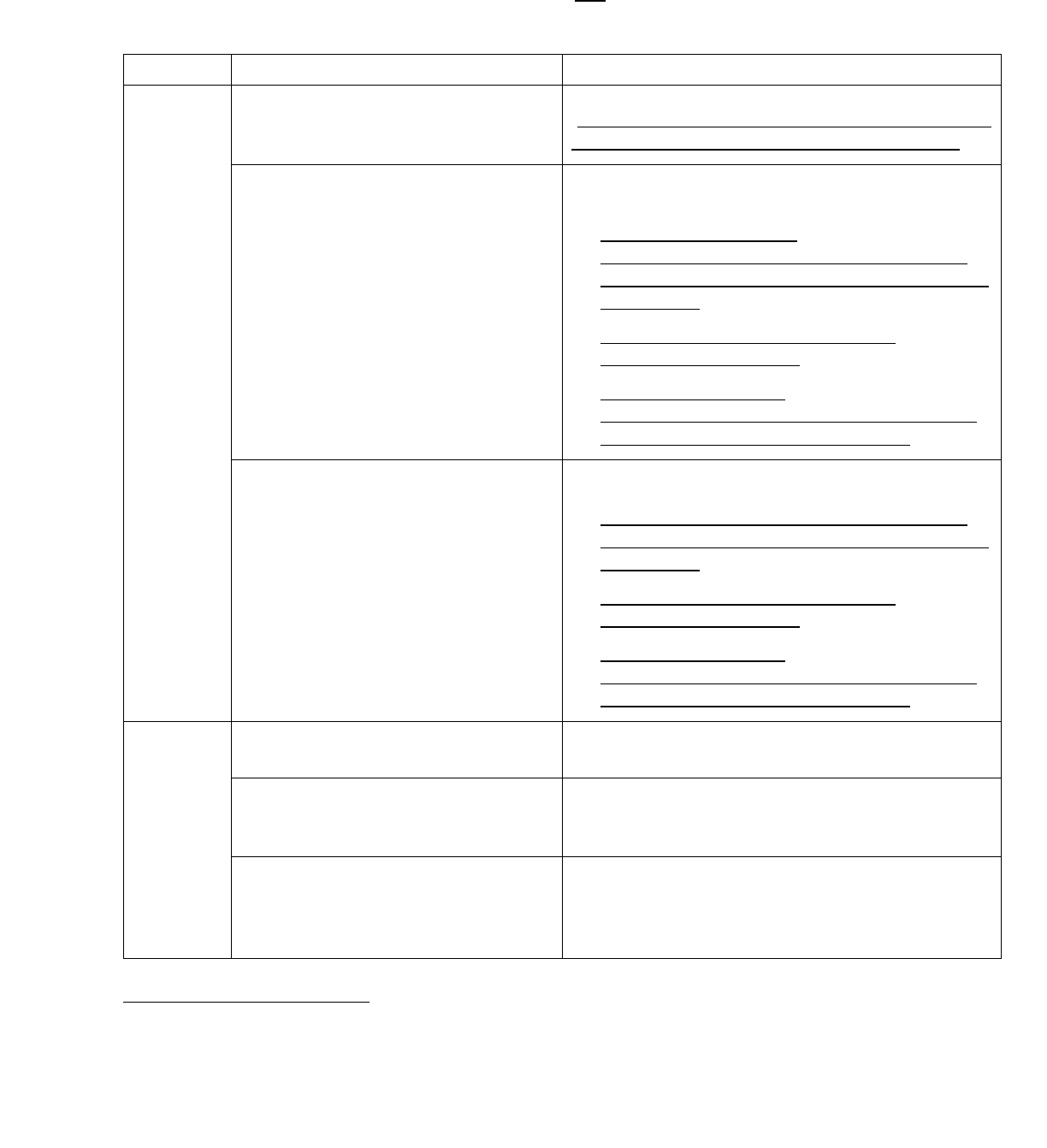

Contents

What’s New Self-Generation Incentive Program (SGIP) .............................................................................. 1

Program Administrator Contact Information .................................................................................................. 8

Program Overview ........................................................................................................................................ 9

1 Budget .................................................................................................................................................. 10

1.1 Statewide Program Budget and Administrator Allocations ......................................................... 10

1.2 Budget Allocation ........................................................................................................................ 10

2 Applications .......................................................................................................................................... 11

2.1 Application Process ..................................................................................................................... 11

2.1.1 Application Process Flowchart ................................................................................................ 11

2.1.1.1 Application Submissions ................................................................................................. 12

2.1.1.1.1 Residential Storage “Soft Target” ............................................................................. 13

2.1.1.1.2 Developer Caps ........................................................................................................ 13

2.1.1.1.3 Lottery Process ......................................................................................................... 13

2.1.1.1.4 Pause Periods ........................................................................................................... 14

2.1.1.1.5 Waitlists ..................................................................................................................... 15

2.1.1.2 Incomplete Applications .................................................................................................. 15

2.1.1.3 Post-Installation Inspections ........................................................................................... 15

2.1.2 Application/Project Modifications, Extensions and Cancellations ........................................... 16

3 Program Participant Eligibility .............................................................................................................. 20

3.1 Host Customer ............................................................................................................................ 20

3.2 Host Customer Eligibility for the Equity, Equity Resiliency, and San Joaquin Valley Budgets ... 20

3.2.1 Residential Equity Eligibility .................................................................................................... 20

3.2.2 Non-Residential Equity Eligibility ............................................................................................. 23

3.2.3 Residential Equity Resiliency Eligibility ................................................................................... 24

3.2.4 Non-Residential Equity Resiliency Eligibility ........................................................................... 25

3

3.2.5 San Joaquin Valley Eligibility .................................................................................................. 28

3.3 Classification of Multifamily Properties ....................................................................................... 28

3.4 System Owner ............................................................................................................................. 29

3.5 Applicant ...................................................................................................................................... 30

3.6 Developer .................................................................................................................................... 30

3.7 Installer ........................................................................................................................................ 32

3.8 Performance Data Provider ......................................................................................................... 32

3.9 Payee .......................................................................................................................................... 32

3.10 Entity ........................................................................................................................................... 33

4 Incentives ............................................................................................................................................. 34

4.1 Incentive Rates............................................................................................................................ 34

4.1.1 General Market Energy Storage Budgets ............................................................................... 34

4.1.2 Energy Storage Equity and Pilot Budgets ............................................................................... 35

4.1.3 Renewable Generation Budget ............................................................................................... 37

4.1.3.1 Renewable Generation Resiliency Adder ....................................................................... 35

4.2 Incentive Calculation ................................................................................................................... 35

4.2.1 Energy Storage Technologies ................................................................................................. 35

4.2.1.1 Incentive Declines Based on Storage Duration .............................................................. 36

4.2.1.2 Incentive Declines and Caps Based on Energy Capacity (Wh) ...................................... 36

4.2.2 Renewable Generation Technologies ..................................................................................... 37

4.2.3 Incentive Declines Based on Generation Rated Capacity ...................................................... 37

4.3 Performance-Based Incentive (PBI) Payment ............................................................................ 37

4.3.1 Energy Storage Technologies ................................................................................................. 37

4.3.1.1 Performance-Based Incentive (PBI) GHG Performance Penalty ................................... 38

4.3.2 Renewable Generation Technologies ..................................................................................... 38

4.3.2.1 PBI Payment Exceedance Cap for Generation Projects................................................. 39

4.3.2.2 PBI Payments for Export to the Grid Projects ................................................................. 39

4

4.4 California Manufacturer Adder .................................................................................................... 39

4.4.1 Eligibility Criteria and Verification ............................................................................................ 39

4.4.2 Project Equipment Verification ................................................................................................ 40

4.4.3 How to Determine Value ......................................................................................................... 40

4.5 Incentive Limitations .................................................................................................................... 40

4.5.1 Maximum Incentive Amount .................................................................................................... 41

4.5.2 Total Eligible Project Costs ..................................................................................................... 41

4.5.3 Incentive Calculation for Site with Multiple Systems ............................................................... 42

4.5.4 Calculating Incentives with Existing Systems ......................................................................... 42

4.5.5 Calculating Incentives for System Replacements ................................................................... 43

4.5.6 Incentives from Other Sources ................................................................................................ 43

5 Program Equipment Requirements ..................................................................................................... 45

6 Energy Storage Technologies ............................................................................................................. 48

6.1 Eligibility Requirements ............................................................................................................... 48

6.1.1 Operational Requirements ...................................................................................................... 48

6.1.2 Paired with On-site Renewables ............................................................................................. 48

6.1.3 Demand Response Dual Participation .................................................................................... 48

6.2 Greenhouse Gas (GHG) Requirements ...................................................................................... 49

6.2.1 Greenhouse Gas Signal .......................................................................................................... 49

6.2.2 New Non-Residential Projects ................................................................................................ 50

6.2.3 Legacy Non-Residential Projects ............................................................................................ 50

6.2.4 New Residential Projects ........................................................................................................ 51

6.2.5 Legacy Residential Projects .................................................................................................... 51

6.3 System Size Parameters ............................................................................................................. 52

6.4 Rating Criteria ............................................................................................................................. 53

6.4.1 Rated Capacity (kW) ............................................................................................................... 53

5

6.4.2 Energy Capacity (kWh) ........................................................................................................... 54

7 Renewable Generation Technologies.................................................................................................. 57

7.1 Operational Eligibility Requirements ........................................................................................... 57

7.1.1 Locational Requirements – IC Engines ................................................................................... 58

7.2 Capacity Factors ......................................................................................................................... 58

7.3 Sizing Requirements ................................................................................................................... 59

7.3.1 System Sizing Limitations - Ineligible Host Customer Loads .................................................. 60

7.4 Renewable Fuel Eligibility Requirements .................................................................................... 61

7.4.1 Directed Biogas Projects ......................................................................................................... 61

7.4.1.1 Directed Biogas Project Renewable Fuel and Fuel Source Audits ................................. 61

7.4.2 On-site Biogas Project Gas Quality Standard for IC Engines ................................................. 62

7.4.3 Hydrogen Projects ................................................................................................................... 62

7.4.4 Pressure Reduction Turbines .................................................................................................. 63

7.5 Fuel Documentation Requirements for PBI ................................................................................ 63

8 Documentation Requirements ............................................................................................................. 65

8.1 Reservation Requests ................................................................................................................. 65

8.2 Proof of Project Milestone ........................................................................................................... 81

8.3 Incentive Claim ............................................................................................................................ 84

9 Metering & Monitoring Requirements .................................................................................................. 88

9.1 Electrical Metering Requirements ............................................................................................... 88

9.1.1 Minimum Electrical Metering Requirements for Energy Storage & Generation Projects ........ 89

9.1.2 Small Thermal Energy Storage Technologies ........................................................................ 91

9.1.3 Refrigeration Thermal Energy Storage Technologies ............................................................. 91

9.1.4 Large Thermal Energy Storage Technologies ........................................................................ 91

9.2 Thermal & Fuel Metering Requirements ..................................................................................... 92

10 Performance Data Provider (PDP) ...................................................................................................... 95

10.1 Application Process ..................................................................................................................... 95

6

10.2 Data Transfer Test ...................................................................................................................... 95

10.3 Metering Requirements ............................................................................................................... 95

10.4 Data Reporting and Transfer Rules ............................................................................................ 96

10.4.1 Data Format ............................................................................................................................ 97

10.4.2 Meter Reading and Data Submission Timeline ....................................................................... 98

10.4.3 Online Submission Process .................................................................................................... 98

10.4.4 PDP Data Validation ............................................................................................................... 98

10.4.5 Data Audits & Payment Validation .......................................................................................... 99

10.4.6 Performance Exemptions ........................................................................................................ 99

10.4.7 Non-Performance .................................................................................................................... 99

10.4.8 Data Retention ...................................................................................................................... 100

10.4.9 Technical and Customer Support .......................................................................................... 101

10.4.10 Program Administrator Liability ............................................................................................. 101

10.5 Data Privacy and Security ......................................................................................................... 101

11 Measurement & Evaluation (M&E) Activities ..................................................................................... 102

11.1 M&E Field Visits ........................................................................................................................ 102

11.2 M&E Metering Requirements .................................................................................................... 102

11.3 Disposition of SGIP Metering Equipment .................................................................................. 102

12 Dispute Resolution ............................................................................................................................. 104

13 Participant Performance and Infractions............................................................................................ 105

13.1 Participant Performance ............................................................................................................ 105

13.1.1 File Retention ........................................................................................................................ 107

13.2 Infractions .................................................................................................................................. 107

13.2.1 Issuance of Warnings and Infractions ................................................................................... 107

14 Program Modification Guidelines ....................................................................................................... 108

Definitions and Glossary ........................................................................................................................... 110

Appendix A – Combustion Emission Credit Calculation ........................................................................... 118

7

Appendix B – Conversion of Emissions PPM to Lb/MWH ........................................................................ 121

Appendix C – Conversion Tables for HVAC-Integrated S-TES ................................................................ 123

Appendix D – Calculation of Minimum Roundtrip Efficiency ..................................................................... 125

Appendix E – Incentive Rate for Large-Scale Storage Projects Claiming the ITC at All Incentive Levels 126

Appendix F – Lg. Thermal Energy Storage UC Davis Methodology for Determining 1-in-10 Year Peak. 127

Appendix G – Lg. Thermal Energy Storage Upfront and PBI Incentive Calculation Methodology ........... 129

Appendix H – Incentive Calculation Examples ......................................................................................... 135

8

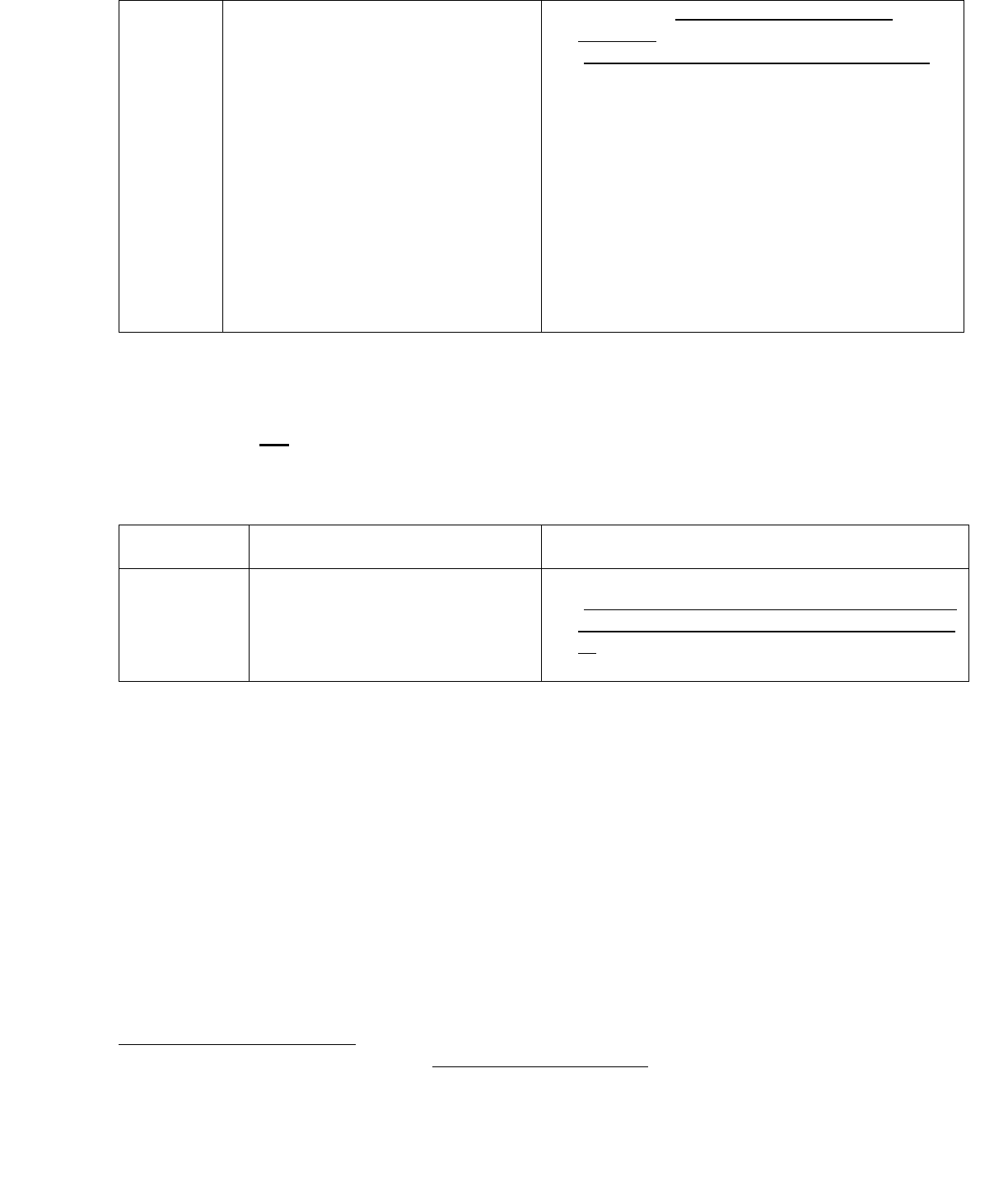

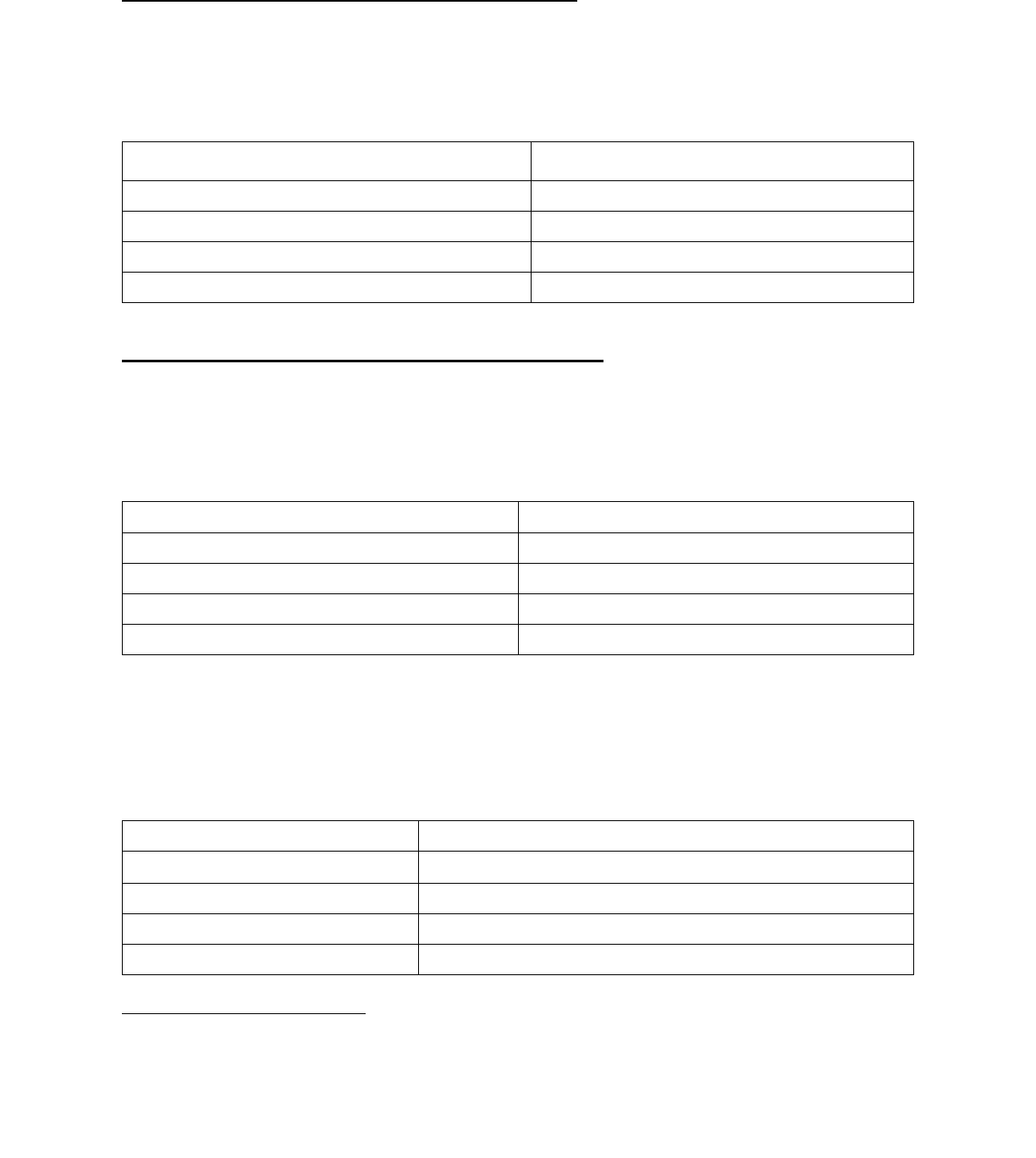

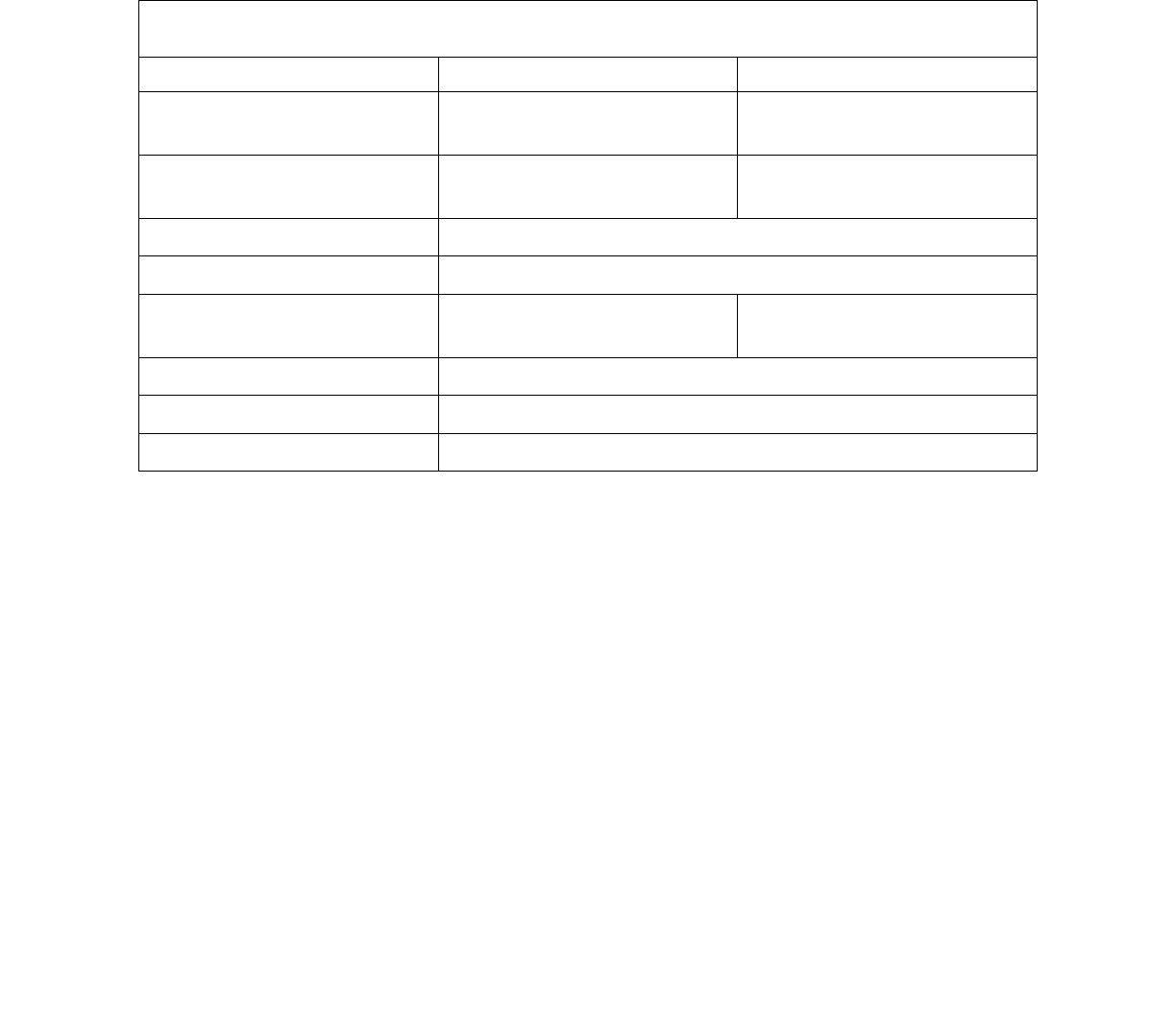

Program Administrator Contact Information

Potential program participants can obtain information and apply for incentive funding through the following

Program Administrators:

1

Pacific Gas & Electric (PG&E)

Website:

www.pge.com/sgip

Email Address:

Telephone:

(415) 973-6436

Mailing Address:

PG&E Payment Research

Attn: Self-Generation Incentive Program

PO Box 997310

Sacramento, CA 95899

Center for Sustainable Energy® (CSE)

Website:

https://sgipsd.org/

Email Address:

Telephone:

(858) 244-1177

Mailing Address:

Center for Sustainable Energy

Attn: Self-Generation Incentive Program

3980 Sherman Street,

Suite 170

San Diego, CA 92110

Southern California Edison (SCE)

Website:

www.sce.com/SGIP

Email Address:

Telephone:

(626) 302-0610

Mailing Address:

Self-Generation Incentive Program

Southern California Edison

P.O. Box 800

Rosemead, CA 91770-0800

Southern California Gas Company (SoCalGas)

Website:

https://www.socalgas.com/for-your-

business/power-generation/self-generation-

incentive

Email Address:

selfgeneration@socalgas.com

Mailing Address:

Self-Generation Incentive Program

Southern California Gas Company

555 West Fifth Street, GT19A9

Los Angeles, CA 90013-1011

1

Potential eligible projects located in the service territory of both Southern California Edison and the Southern California Gas

Company can apply for incentive funding to either Program Administrator, but not to both.

9

Program Overview

The Self-Generation Incentive Program (SGIP) provides financial incentives for the installation of new

qualifying technologies that are installed to meet all, or a portion of the electric energy needs of a facility.

The purpose of the SGIP is to contribute to Greenhouse Gas (GHG) emissions reductions, demand

reductions and reduced customer electricity purchases, resulting in the electric system reliability through

improved transmission and distribution system utilization; as well as market transformation for distributed

energy resource (DER) technologies.

This handbook outlines the policies and procedures of the SGIP for potential program participants and

other interested parties. The SGIP has been approved by the California Public Utilities Commission

(CPUC) and is subject to change in whole or in part at any time without prior notice. Changes to the

program shall be published in revisions to this Handbook. The Program Administrators (PAs) are Pacific

Gas and Electric (PG&E), Southern California Edison (SCE), the Southern California Gas Company

(SoCalGas) and Center for Sustainable Energy

®

(CSE).

2

2

CSE is the Program Administrator for San Diego Gas & Electric (SDG&E) customers.

10

1 Budget

1.1 Statewide Program Budget and Administrator Allocations

Authorized incentive collections during program years 2020 through 2024 total $813,400,000. Authorized

incentive collections for each Program Administrator are as follows:

Pacific Gas and Electric Company $360,000,000

Southern California Edison Company $280,000,000

Center for Sustainable Energy $99,000,000

Southern California Gas Company $74,400,000

The SGIP shall be administered on a continuous basis. Program Administrators will issue incentive

reservations for any budget with available funds through December 31, 2025.

3

Should it appear likely that

funds will remain unspent, the PAs may transfer funds between budgets prior to December 31, 2025. A

budget overview, including funding availability and current incentive rates, can be found at

www.selfgenca.com/home/program_metrics/.

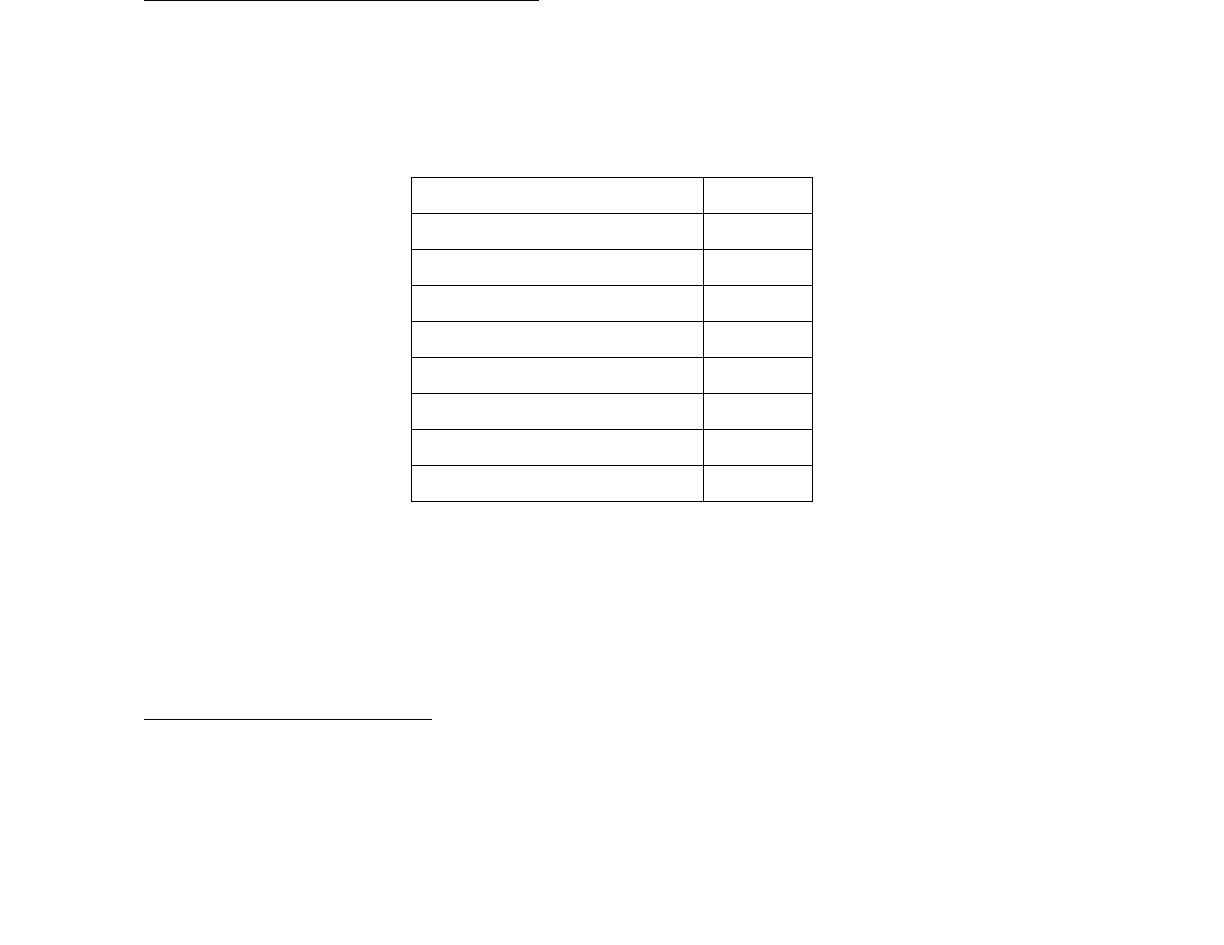

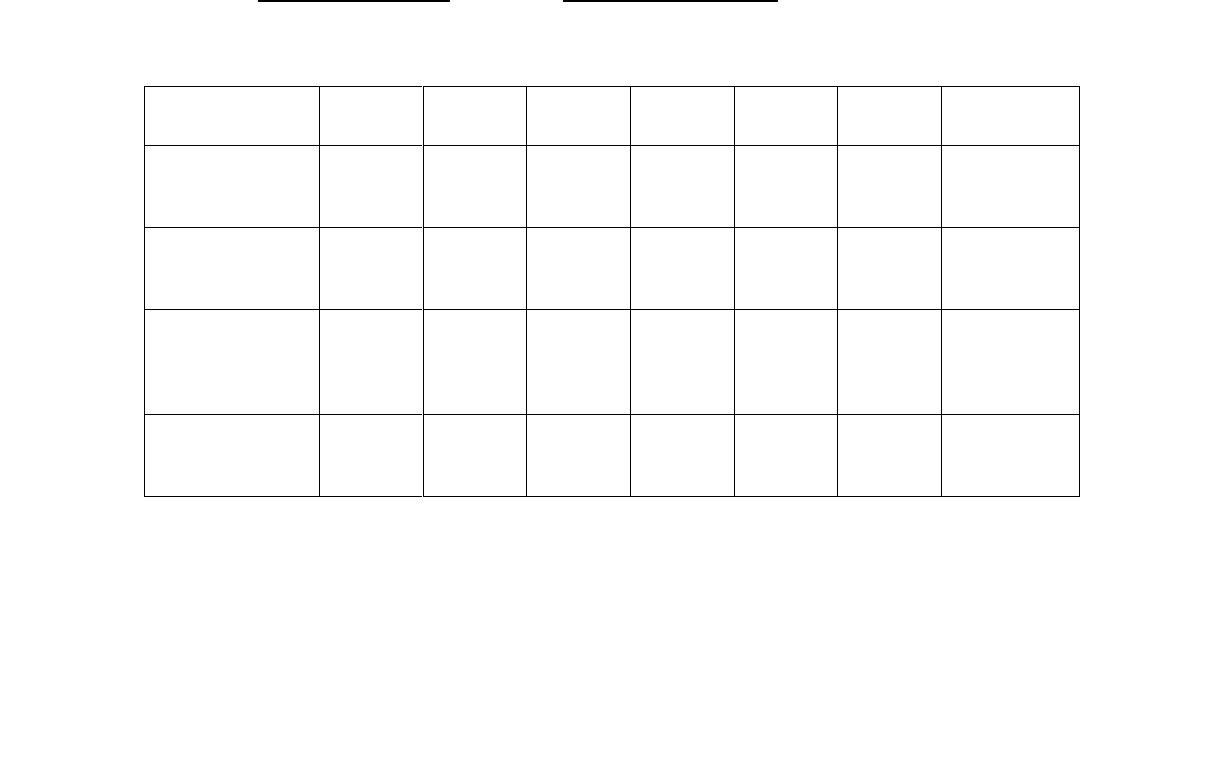

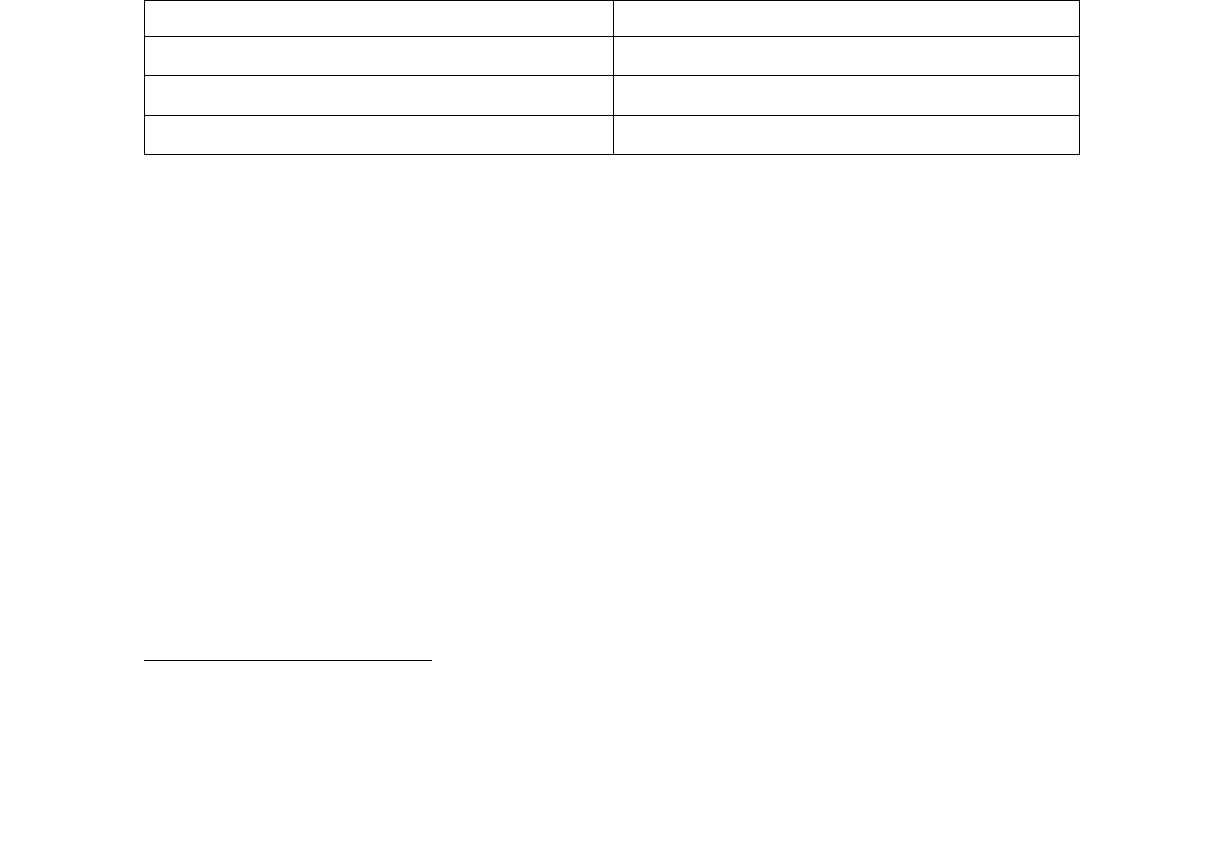

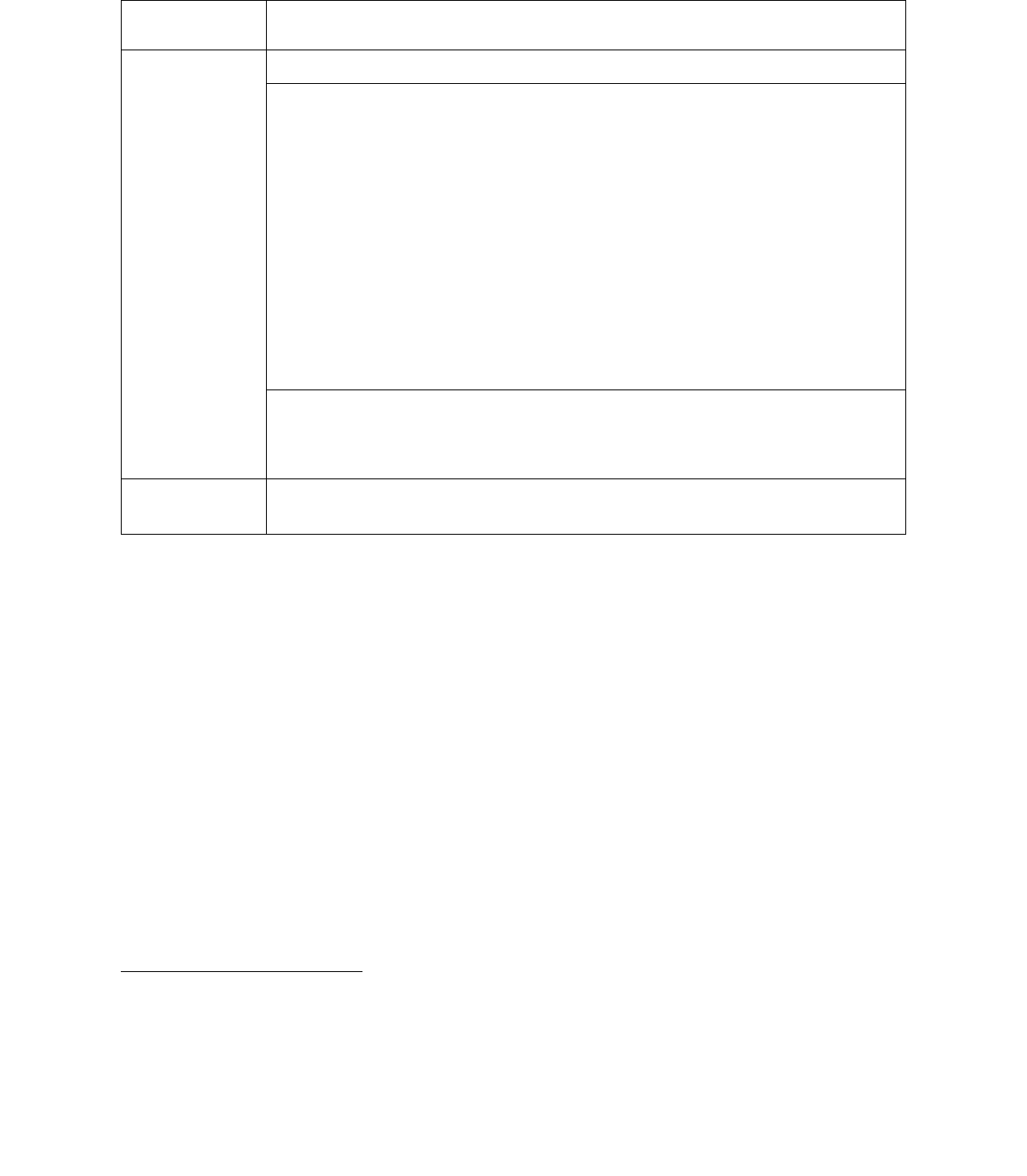

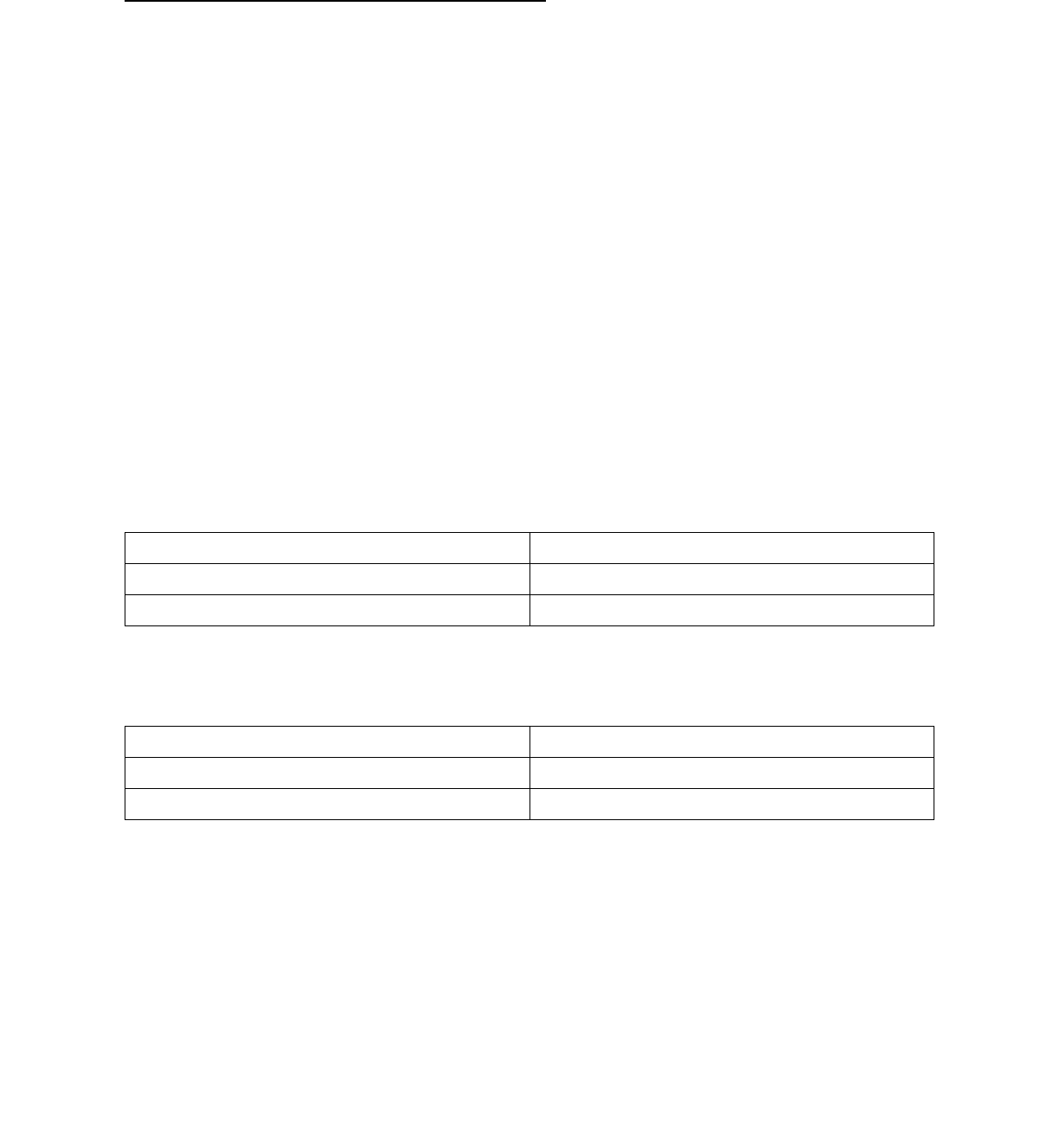

1.2 Budget Allocation

Statewide budget allocations of the 2020 – 2024 ratepayer collections are as follows:

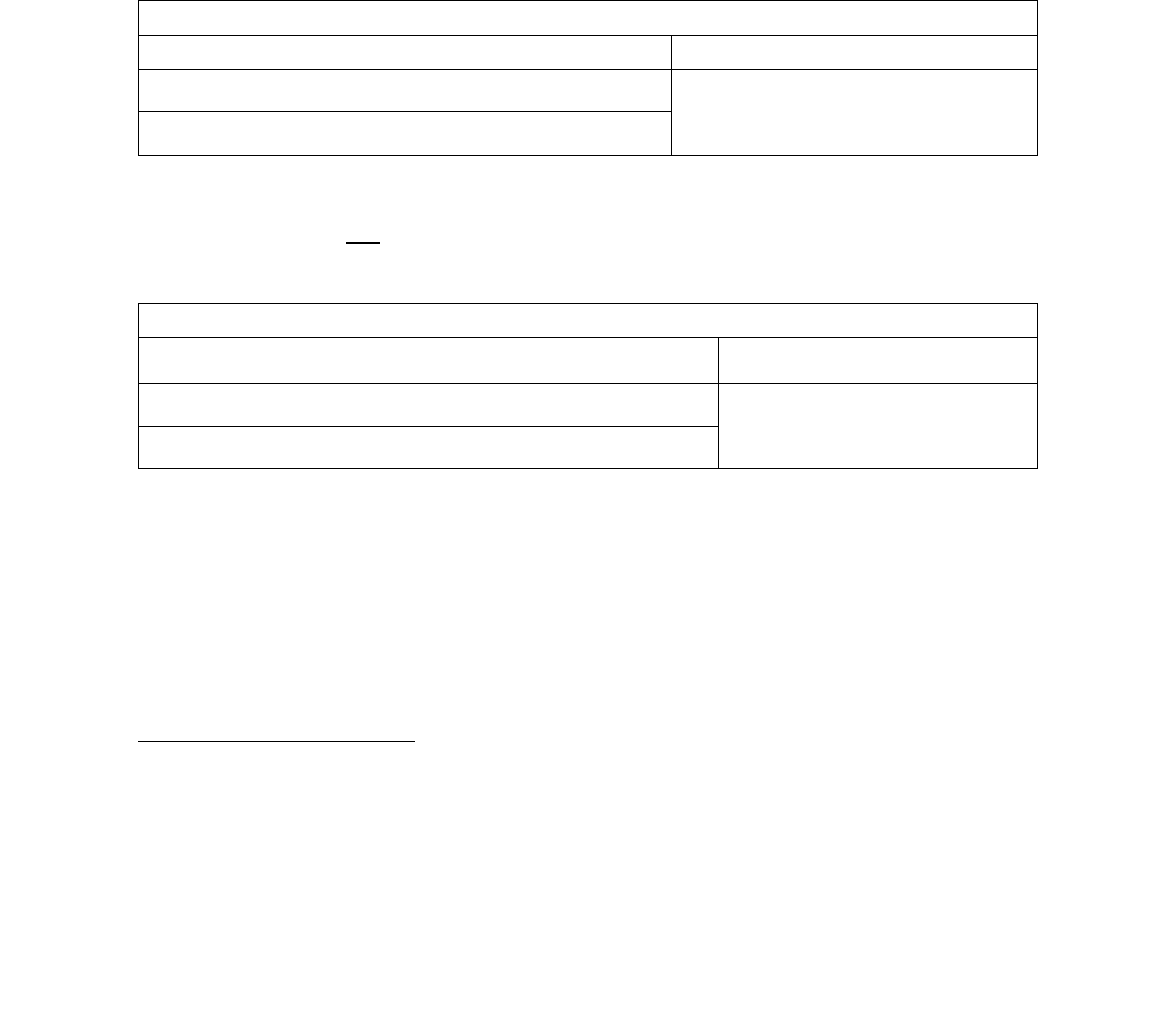

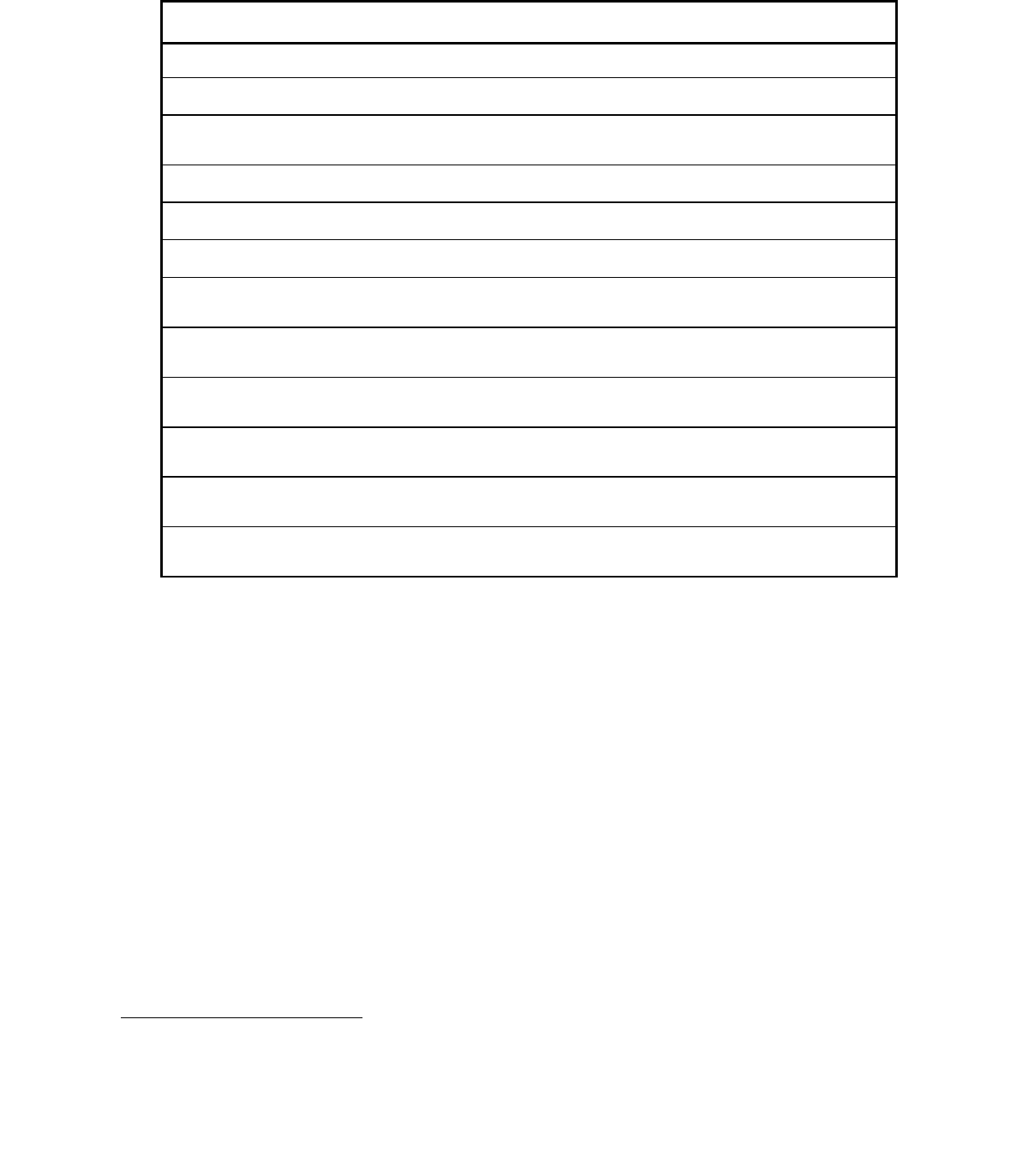

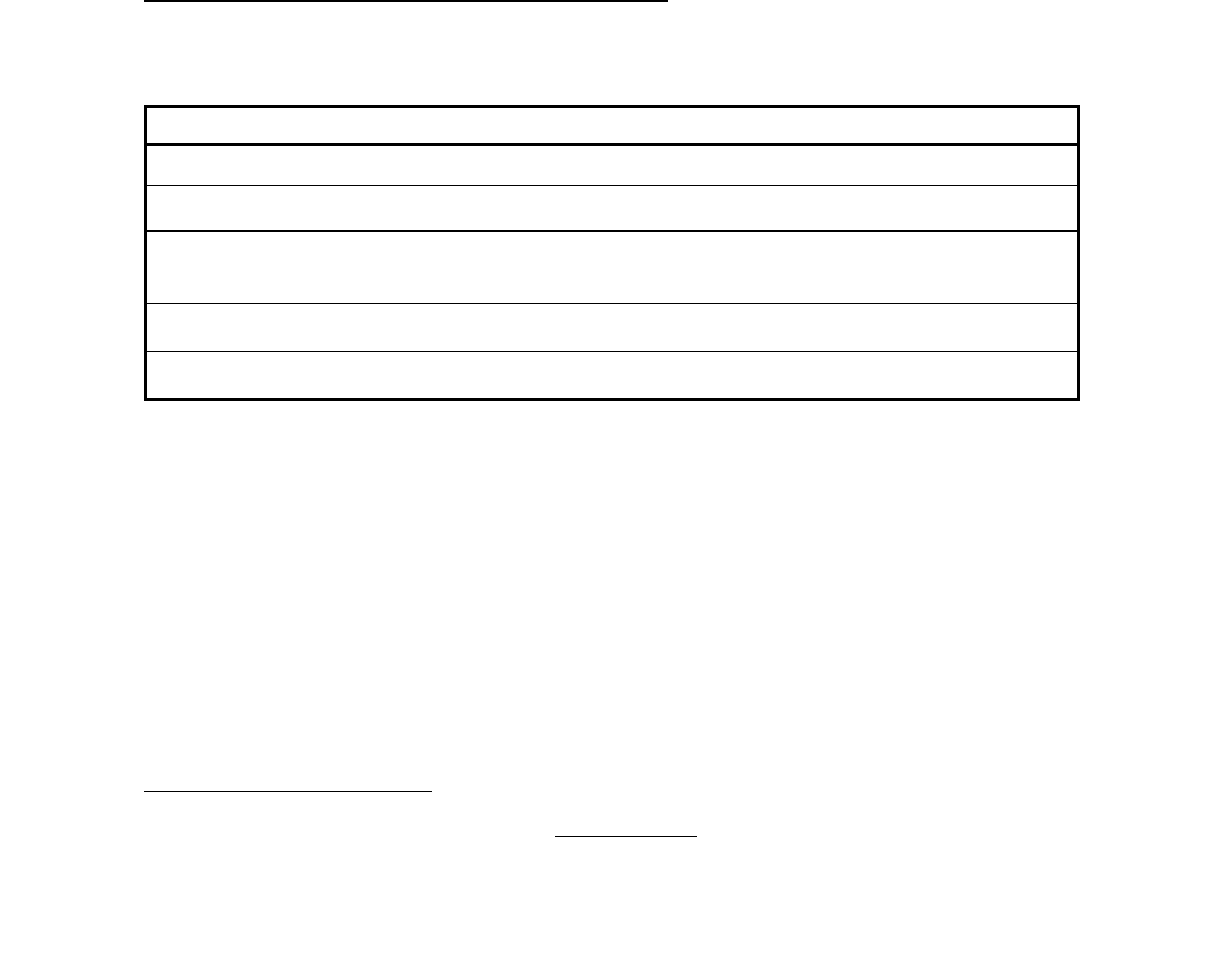

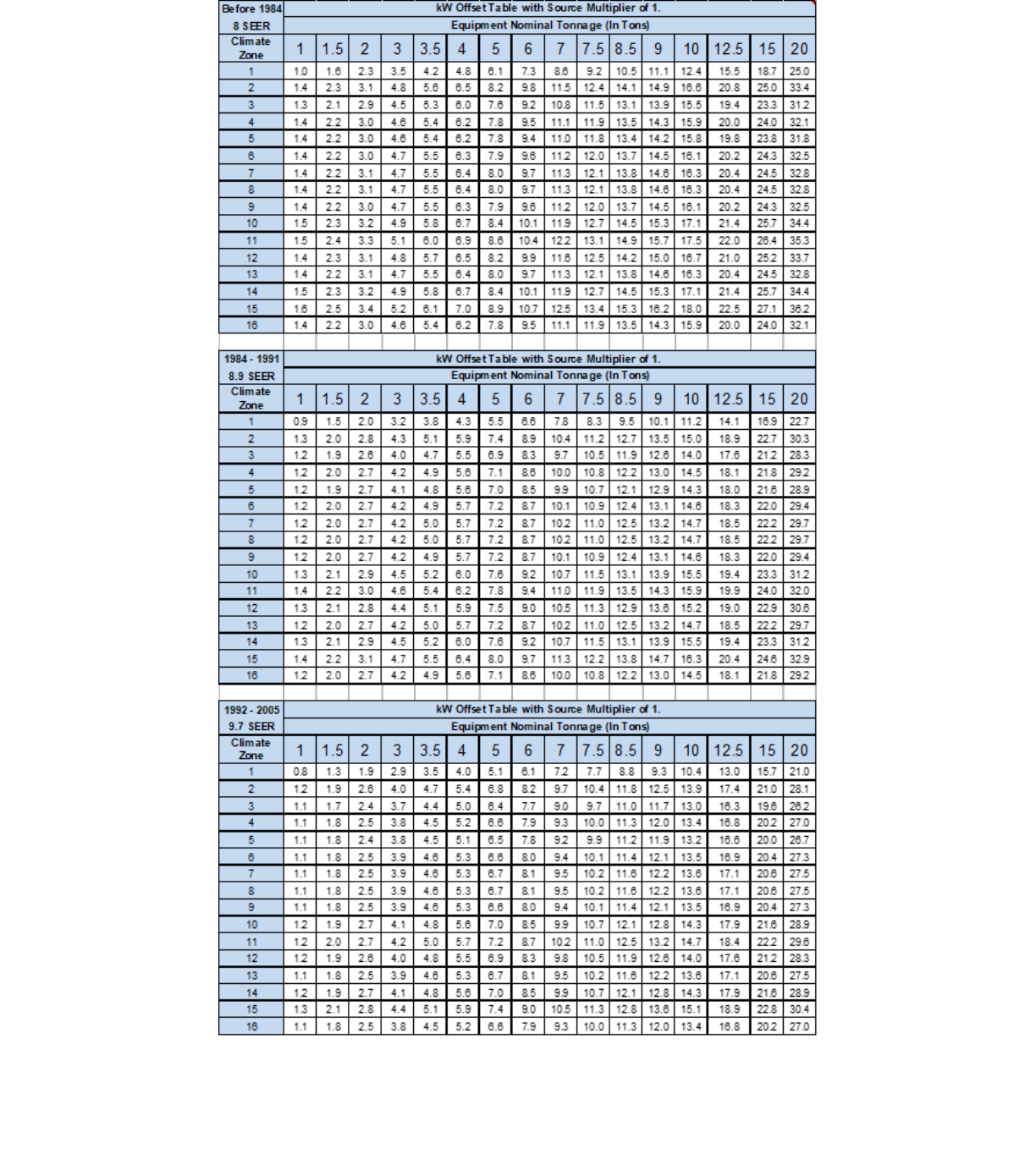

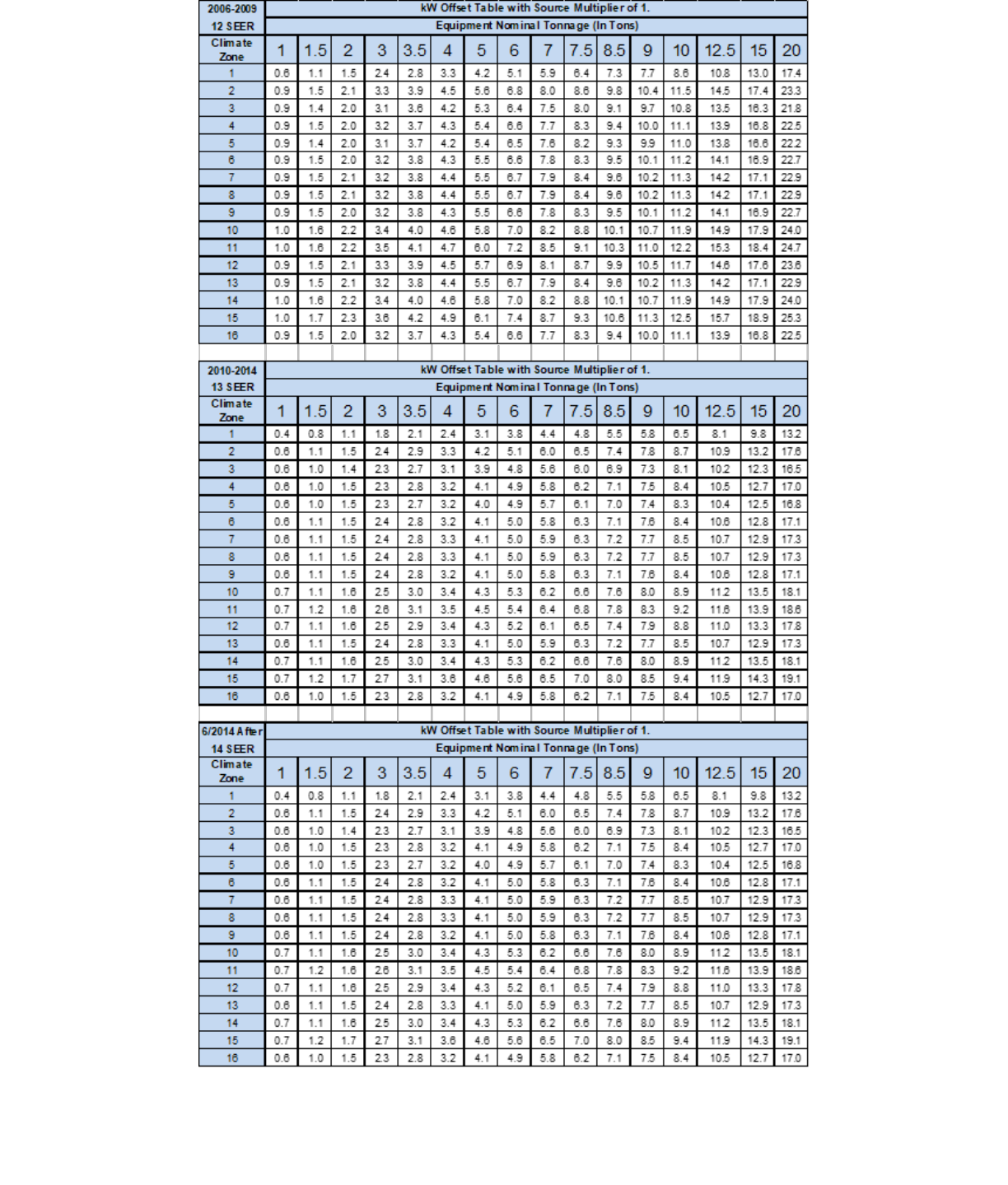

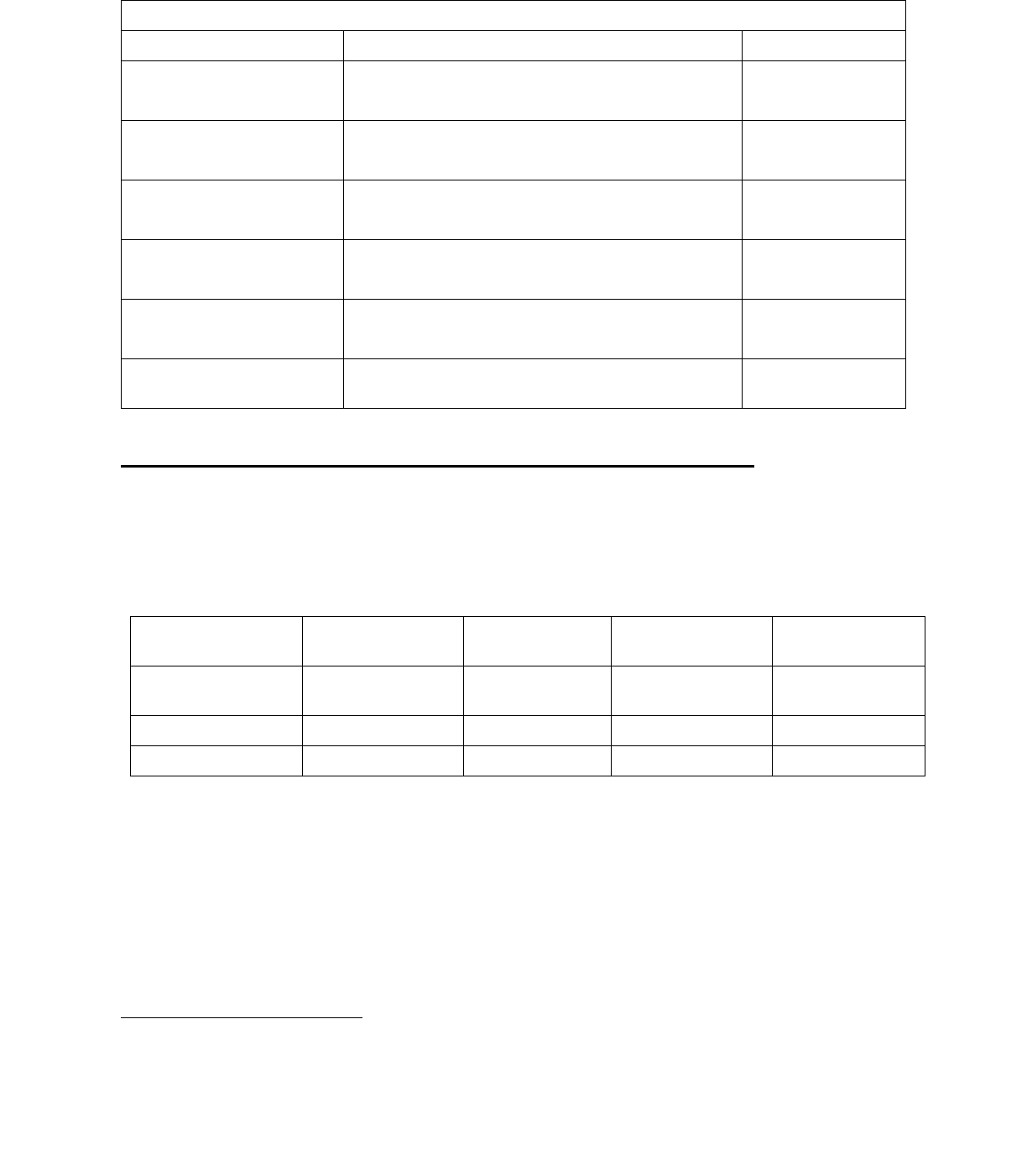

Table 1.2: Statewide budget allocations

Renewable Generation

12%

Energy Storage Technologies

88%

Large-Scale Storage

10%

Small Residential Storage

7%

Residential Equity

3%

Non-Residential Equity

0%

Equity Resiliency

63%

Heat Pump Water Heaters

5%

4

SJV Pilot Budget

0%

3

Incentive funds include authorized ratepayer collections, returned funds from project attrition, application fee forfeitures, and

accrued interest.

4

D.22-04-036, Ordering Paragraph 8, authorized an additional collection of $40M from 2023 Cap-and-Trade Program allowance

auction funds from SoCalGas, PG&E, and SDG&E for the HPWH subprogram.

11

2 Applications

2.1 Application Process

Applications are subject to the incentive rates of the Program Administrator to which they apply.

Generally, applications will be assigned an incentive rate and reviewed in the order in which they are

received. A lottery will be conducted in the event that application submissions for a given budget and step

on a single day exceed the available funding in a given Program Administrator’s territory. Additional

details regarding the lottery process can be found in Section 2.1.1.1.3.

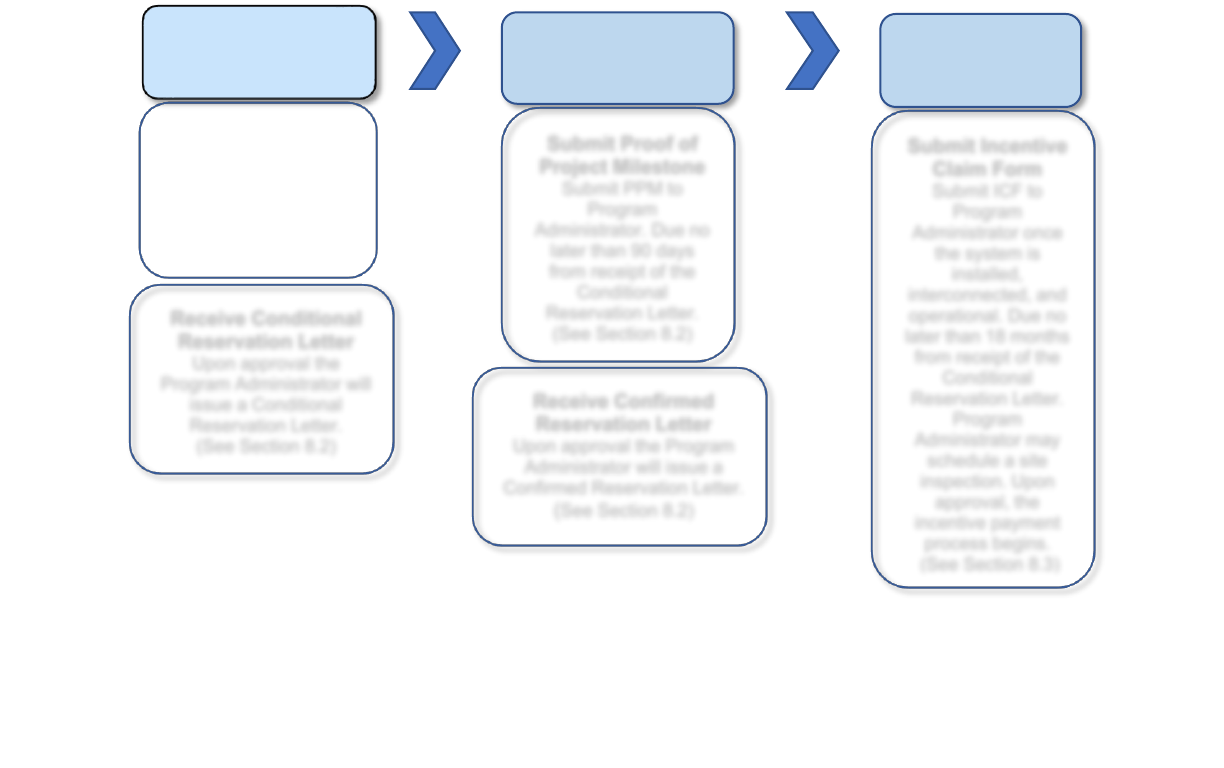

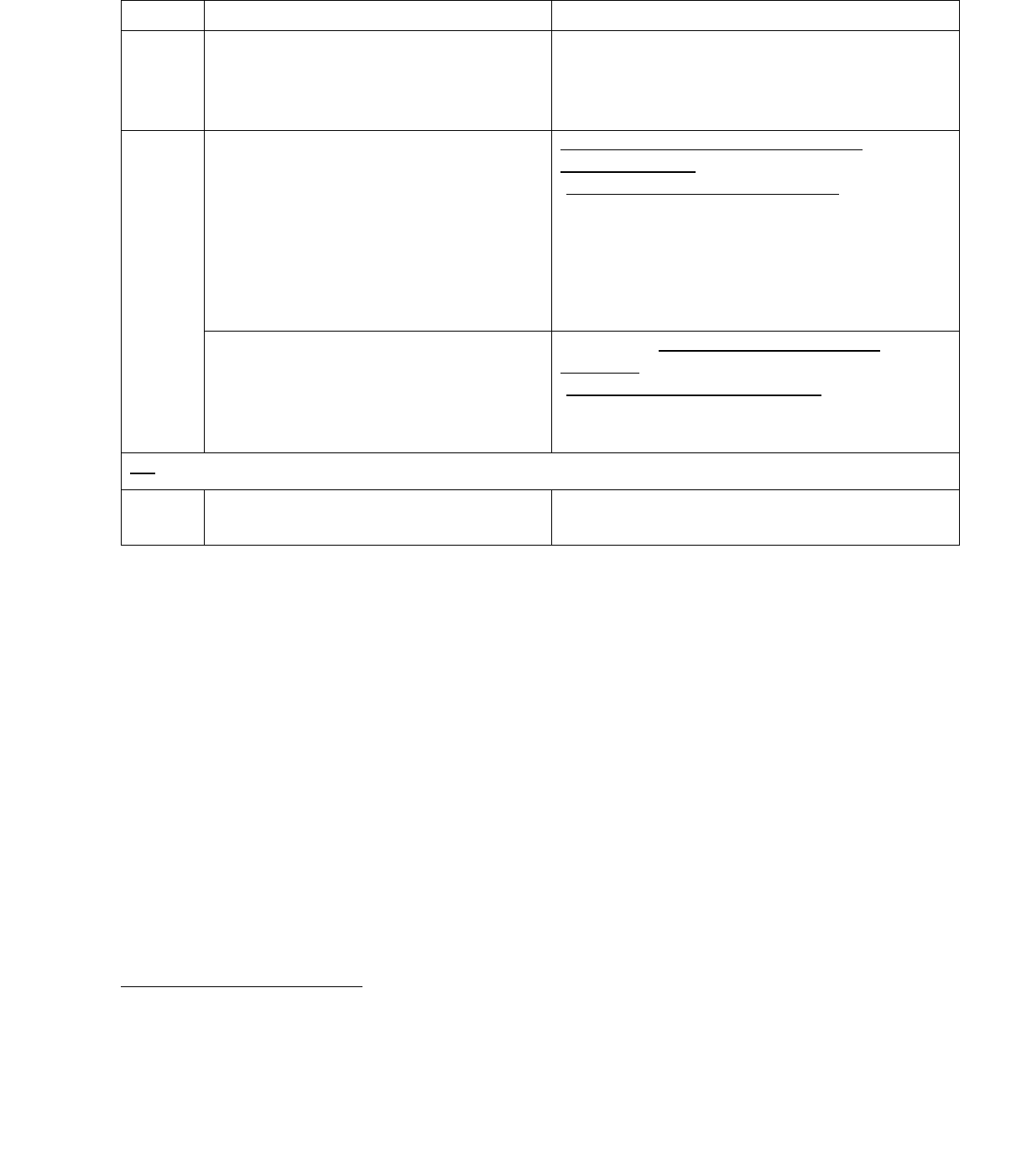

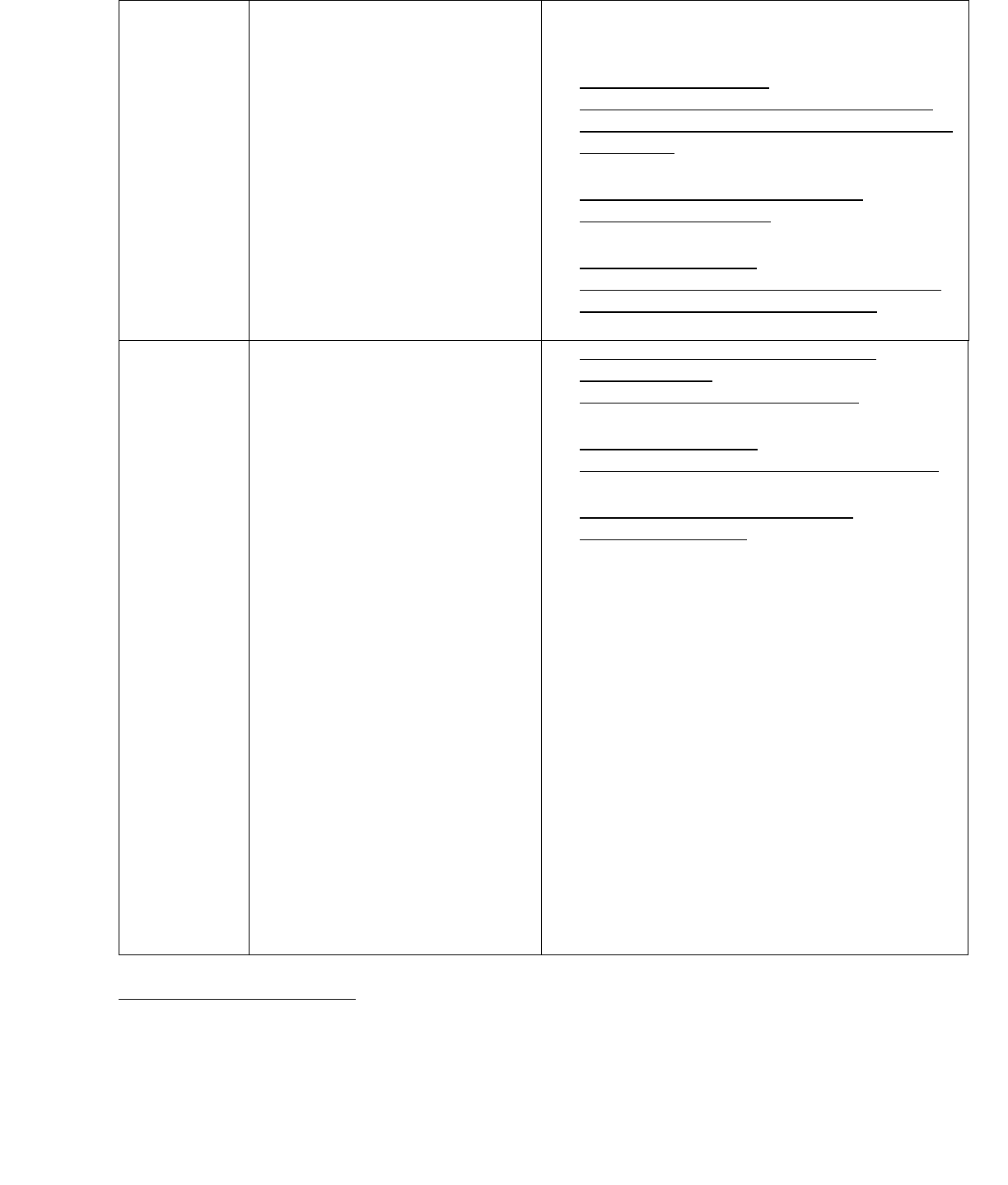

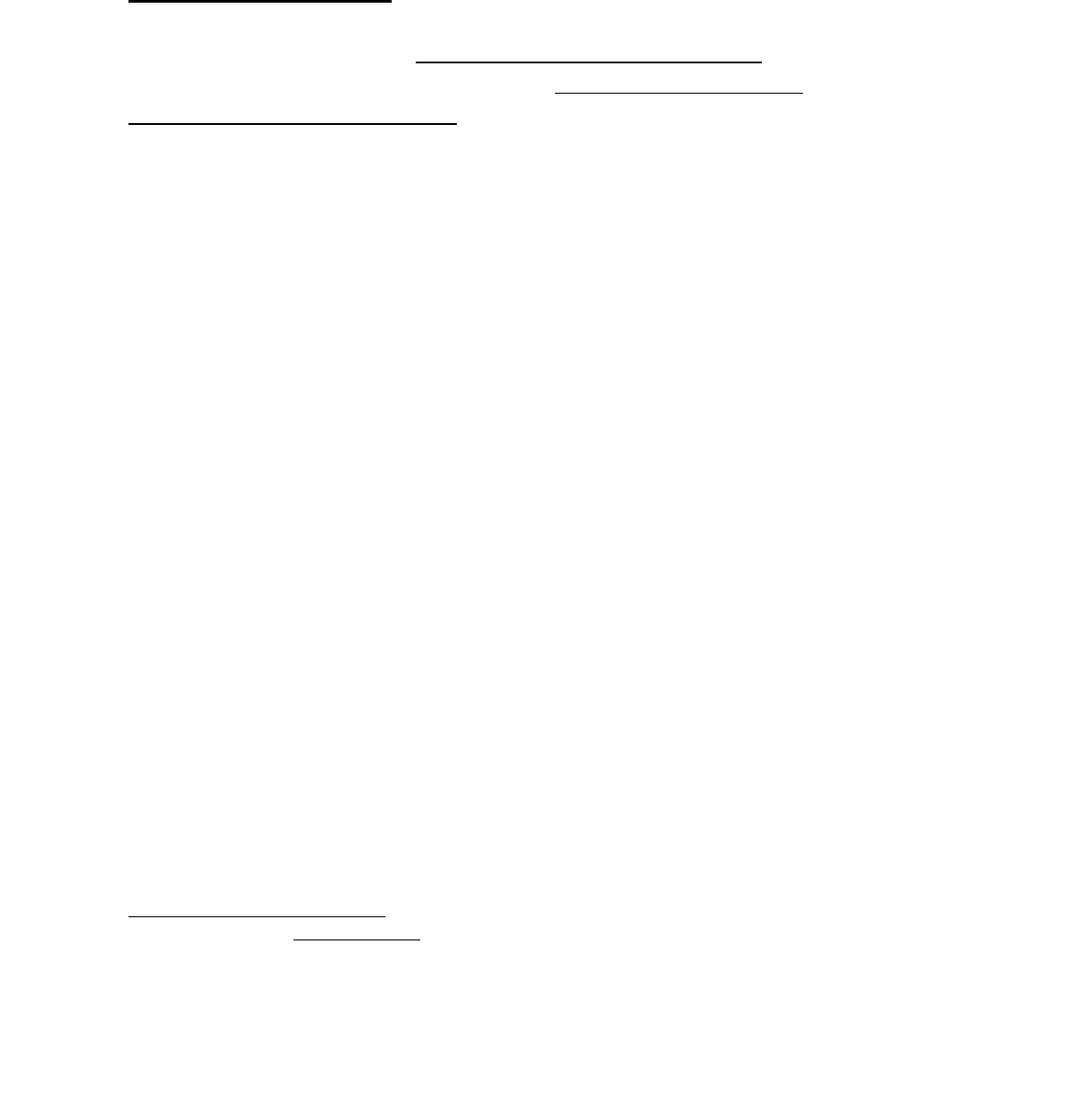

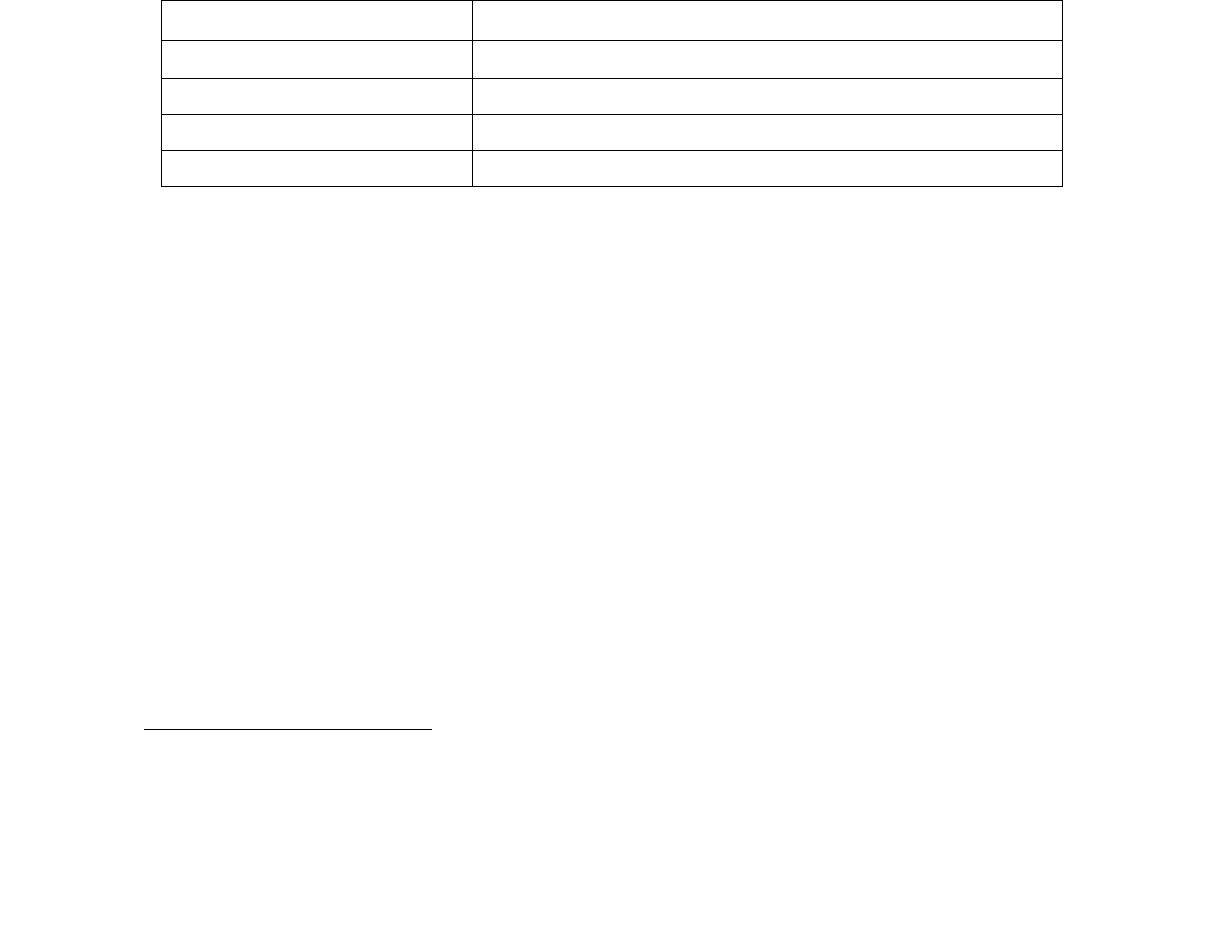

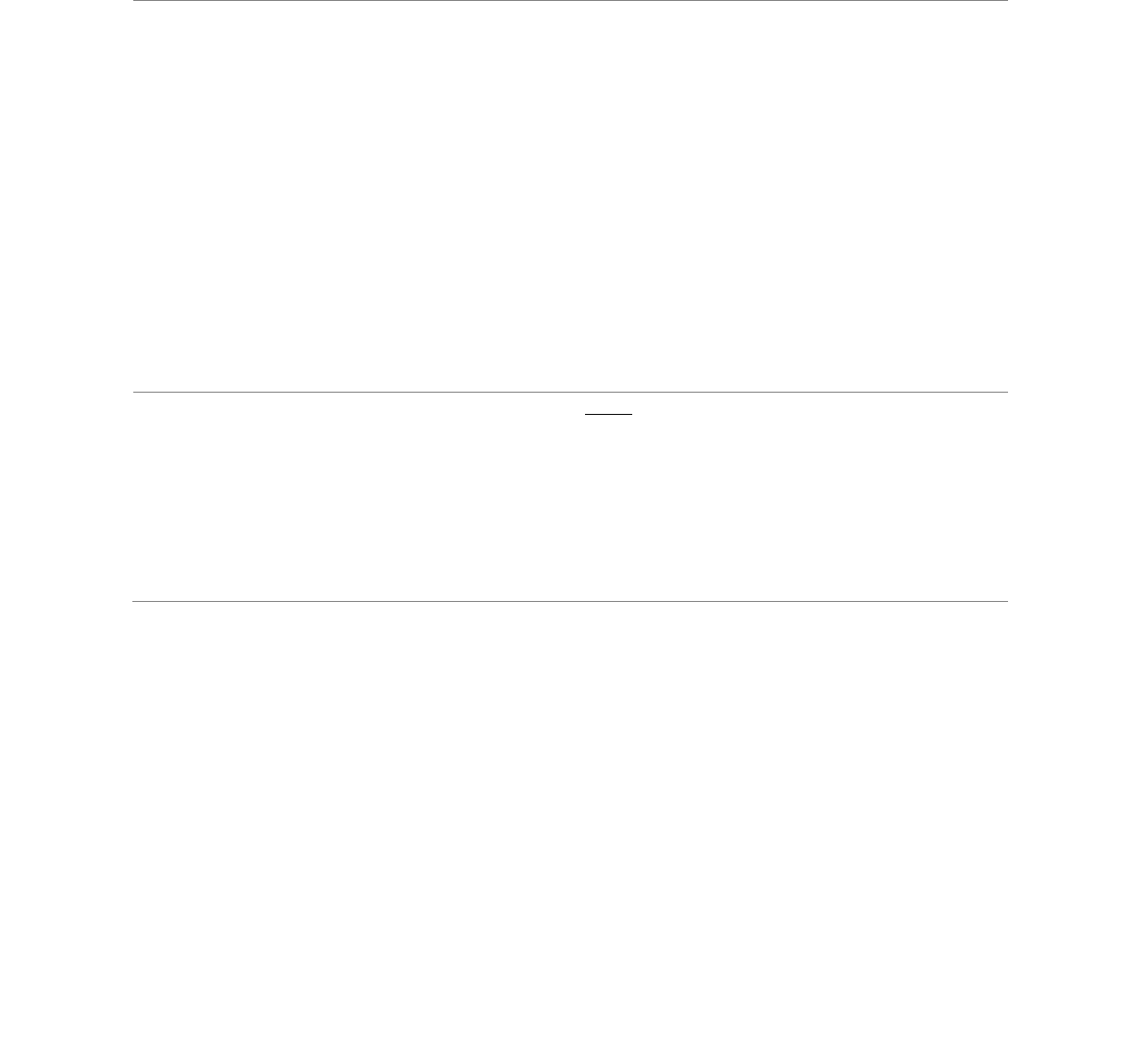

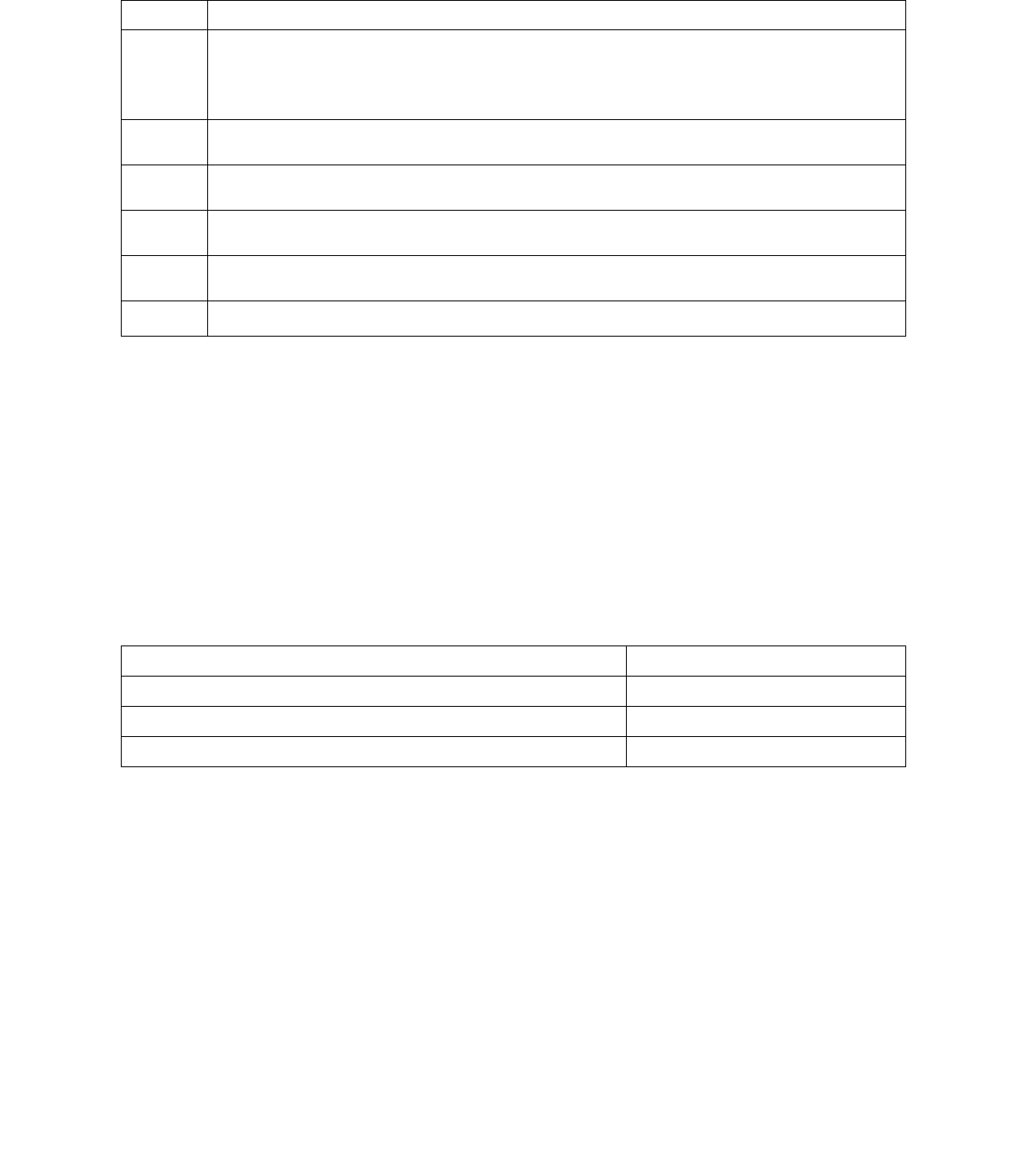

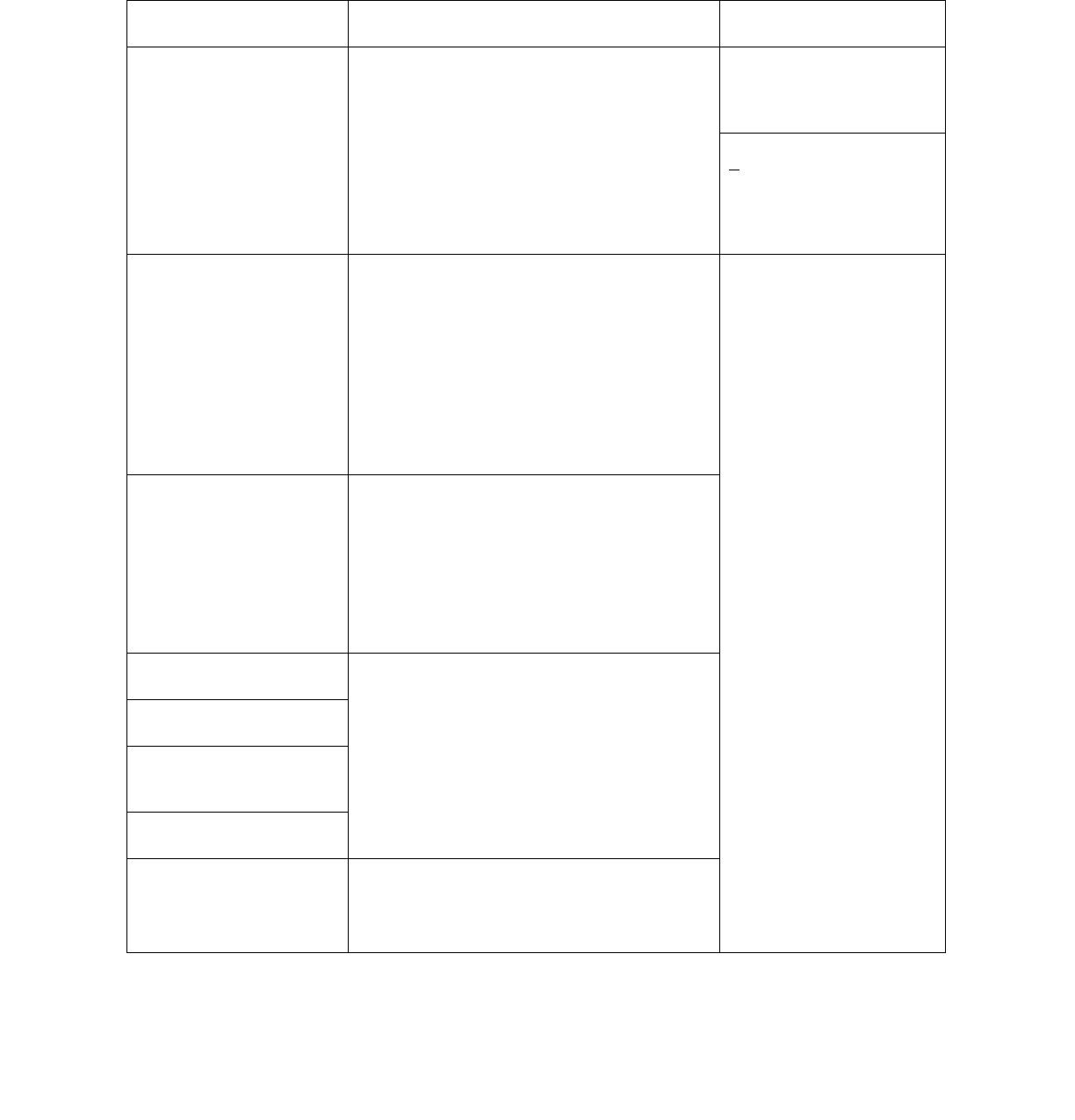

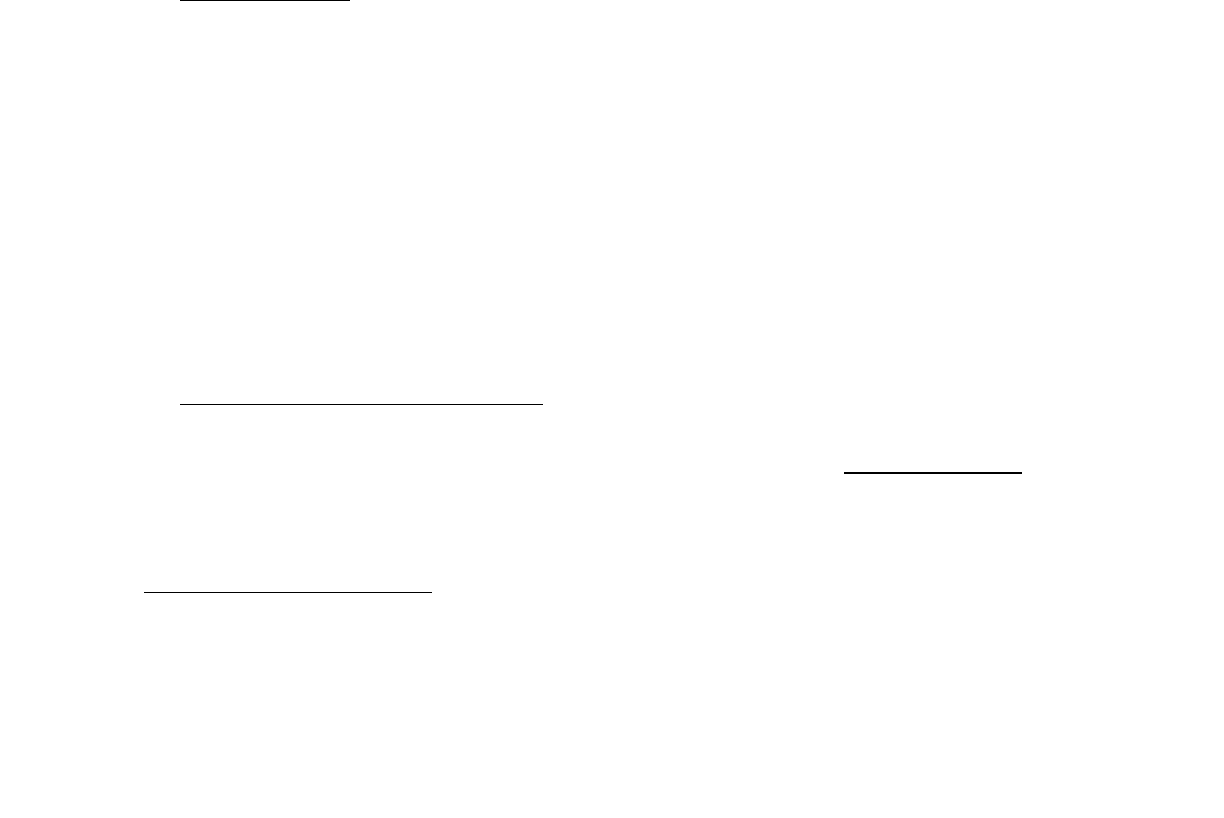

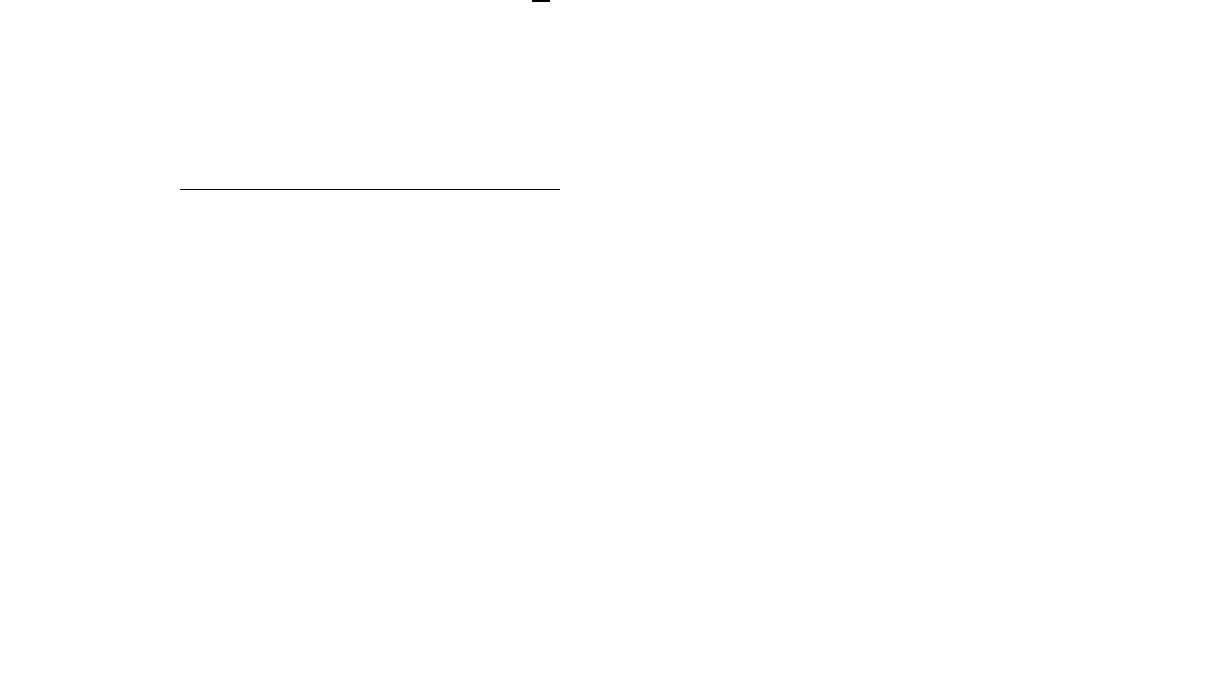

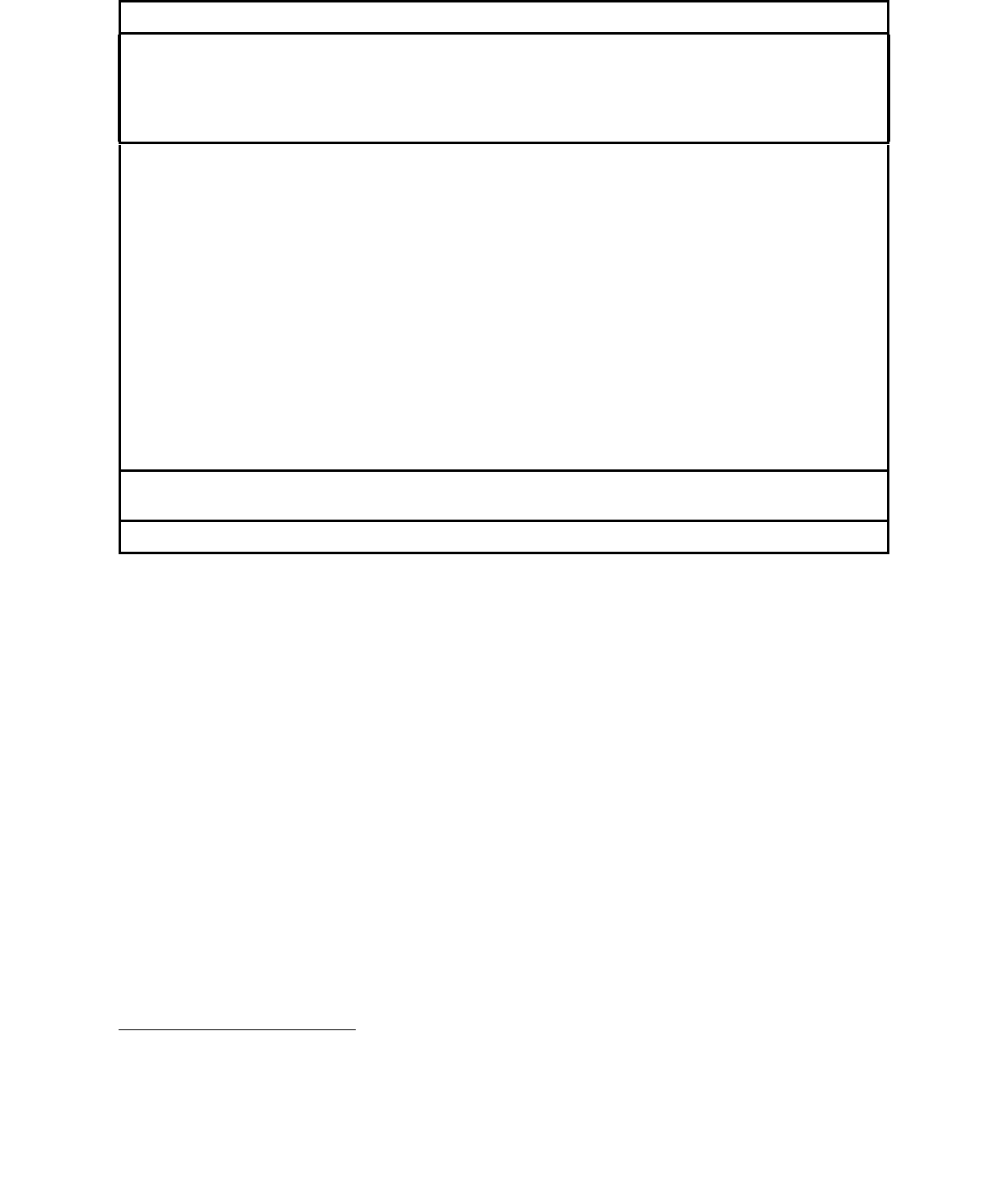

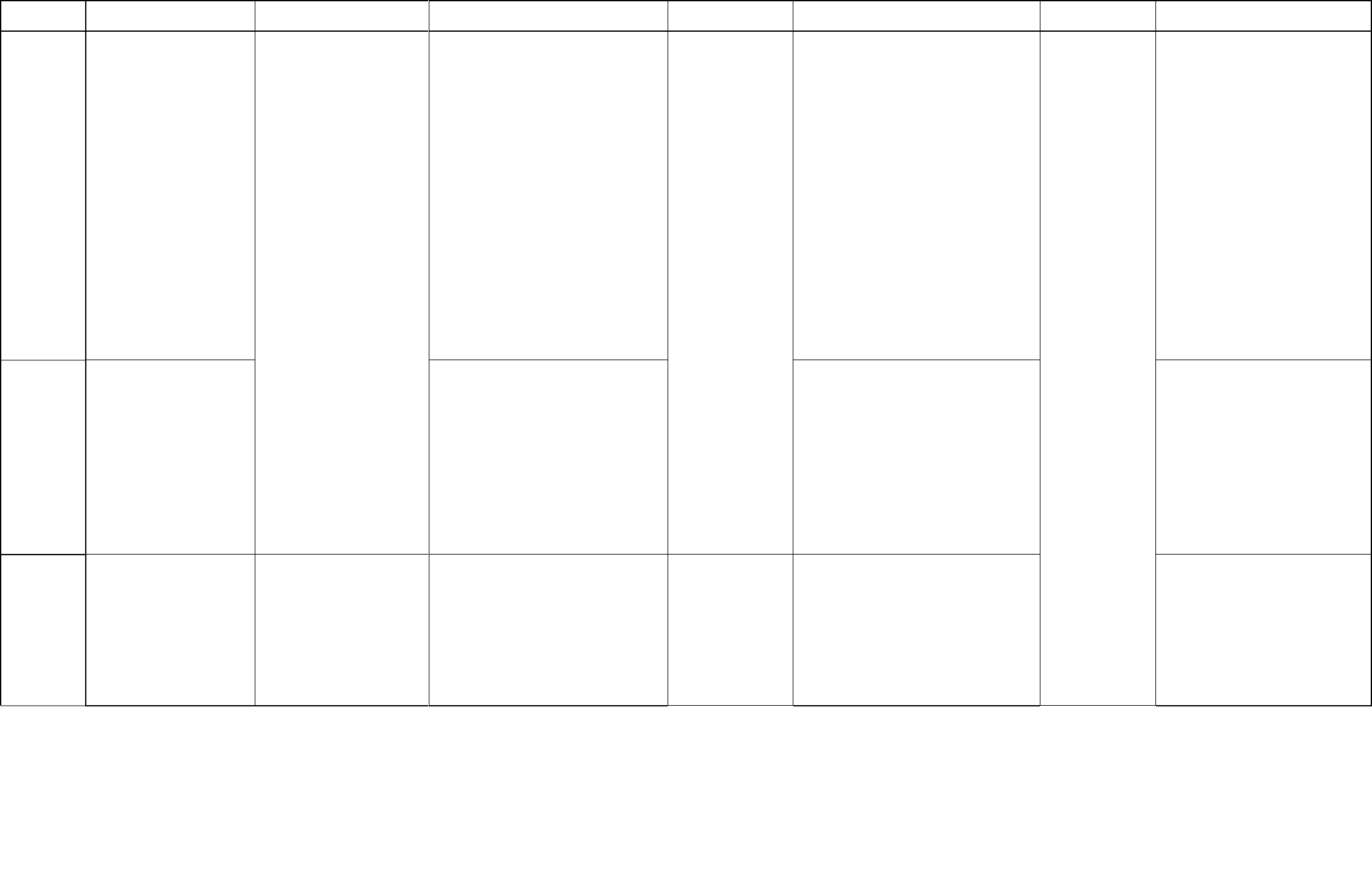

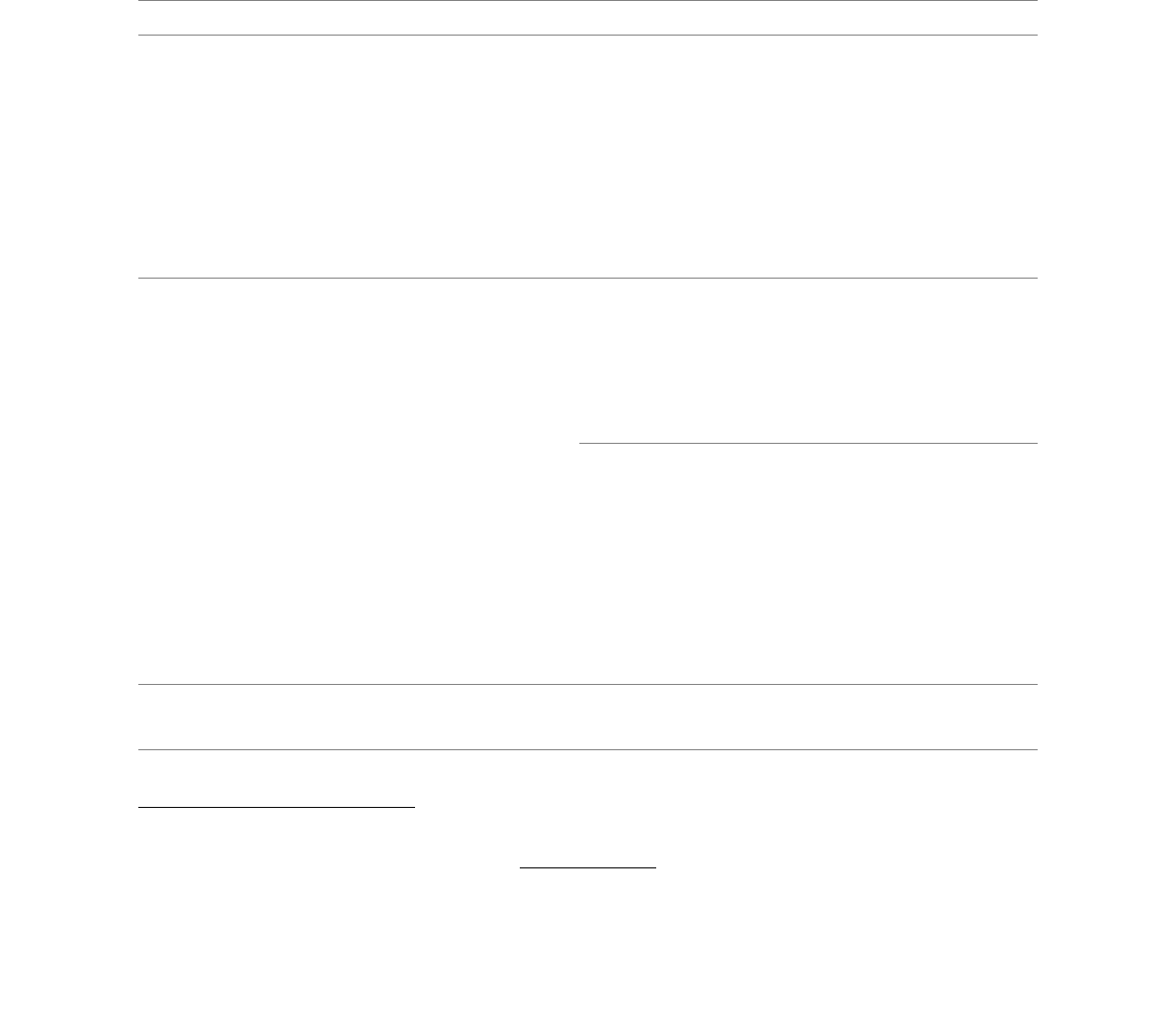

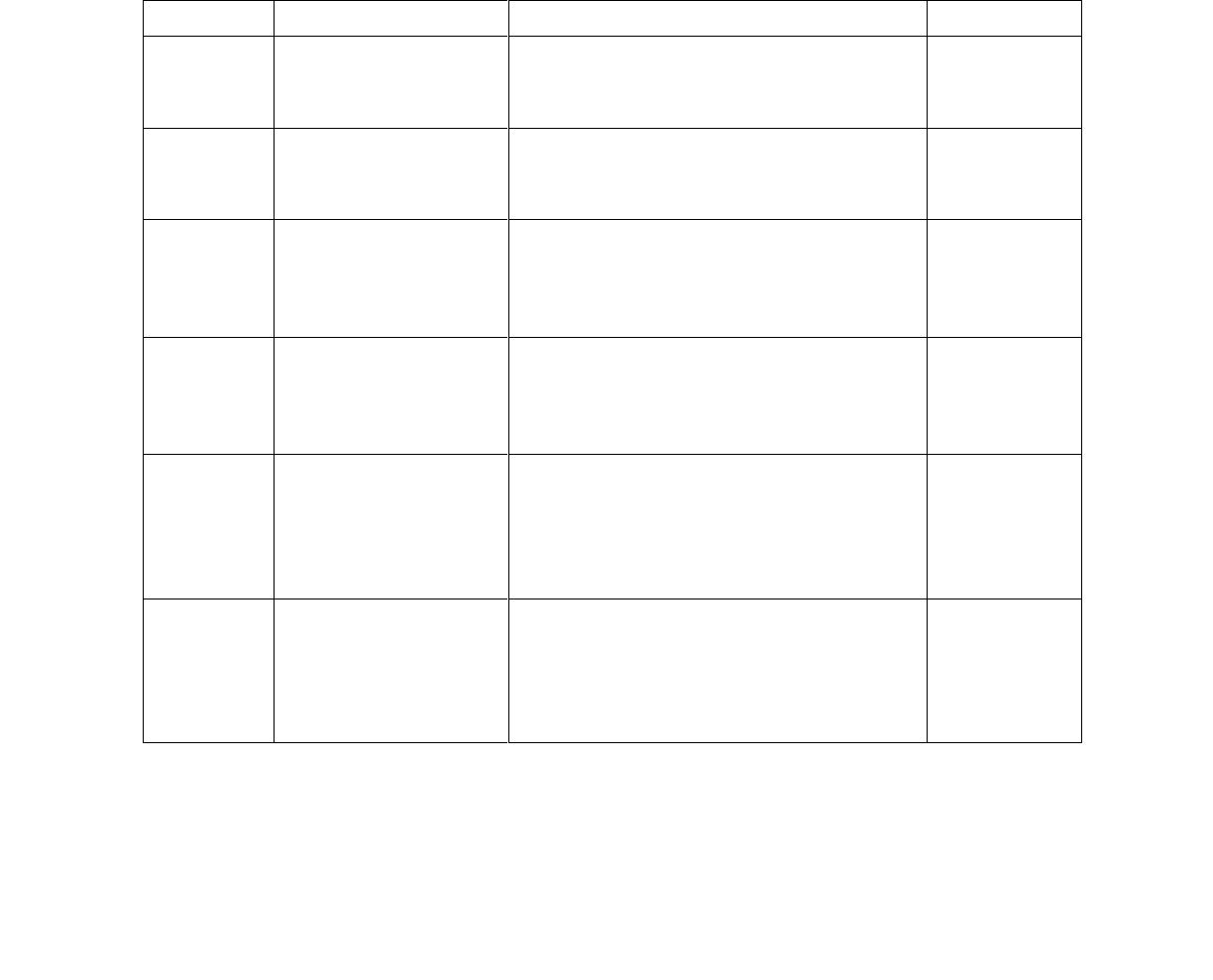

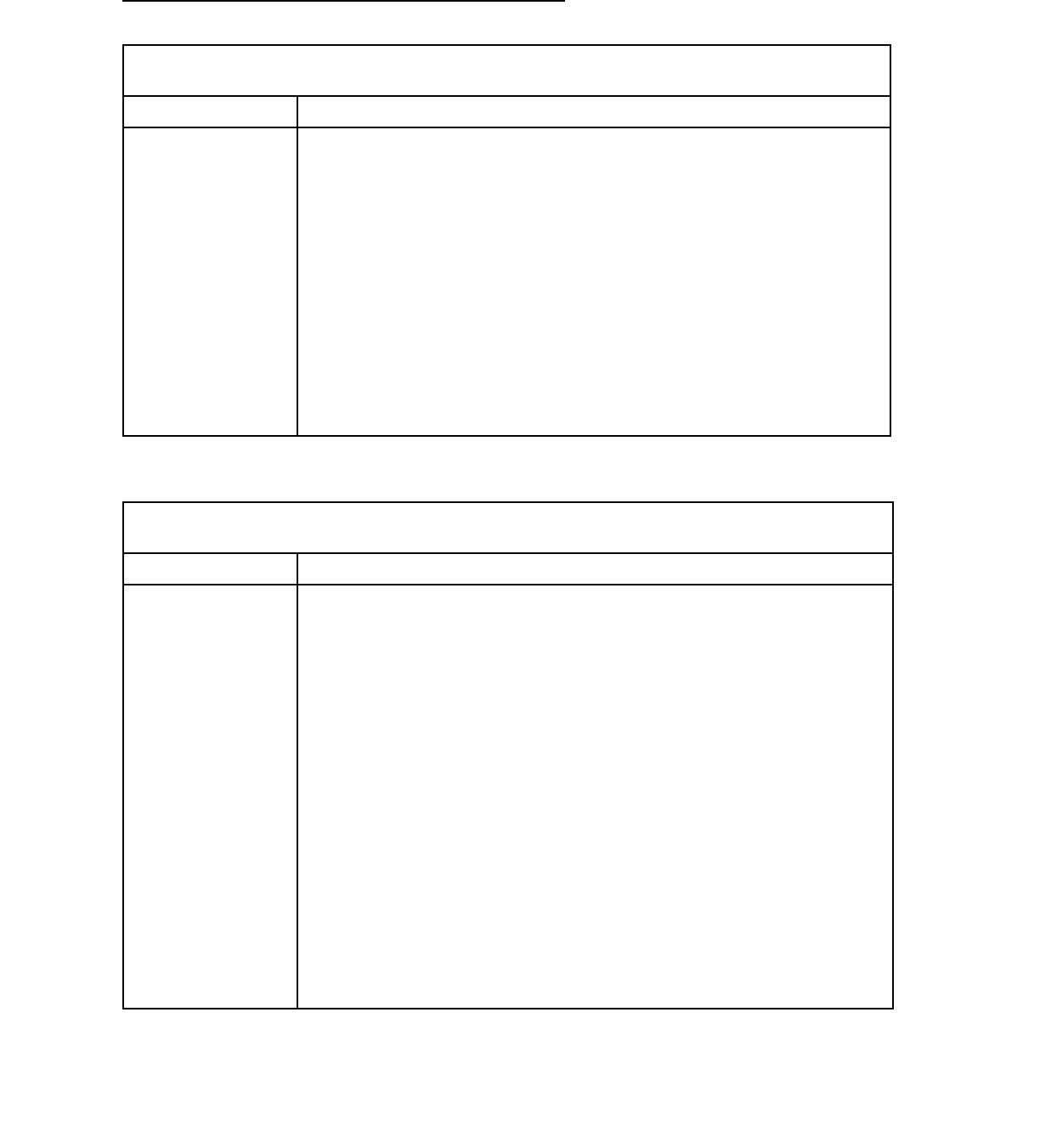

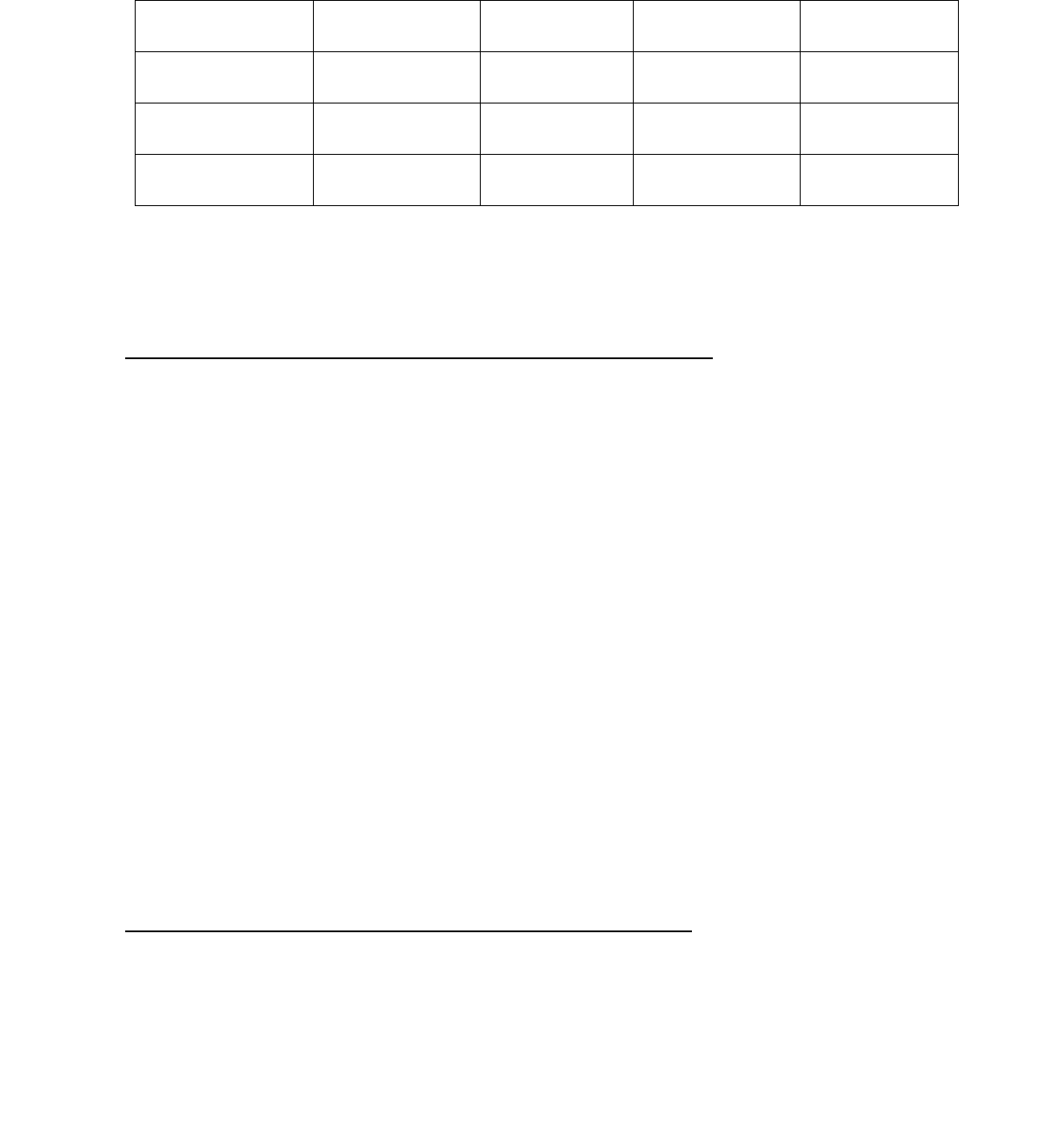

2.1.1 Application Process Flowchart

The application process is determined by the customer sector and system size. There are two application

processes illustrated below:

1. Three-Step Application Process – Figure 2.1.1a

• Non-residential projects 10 kW or greater

2. Two-Step Application Process – Figure 2.1.1b

• All residential projects

• Non-residential projects less than 10 kW

Figure 2.1.1a: Three-Step Application and Approval Process

Reservation

Request (RRF)

Proof of Project

Milestone

(PPM)

Incentive

Claim

(ICF)

Submit Reservation

Request Form

Submit completed RRF

to Program

Administrator.

(See Section 8.1)

Submit Proof of

Project Milestone

Submit PPM to

Program

Administrator. Due no

later than 90 days

from receipt of the

Conditional

Reservation Letter.

(See Section 8.2)

Receive Conditional

Reservation Letter

Upon approval the

Program Administrator will

issue a Conditional

Reservation Letter.

(See Section 8.2)

Receive Confirmed

Reservation Letter

Upon approval the Program

Administrator will issue a

Confirmed Reservation Letter.

(See Section 8.2)

Submit Incentive

Claim Form

Submit ICF to

Program

Administrator once

the system is

installed,

interconnected, and

operational. Due no

later than 18 months

from receipt of the

Conditional

Reservation Letter.

Program

Administrator may

schedule a site

inspection. Upon

approval, the

incentive payment

process begins.

(See Section 8.3)

12

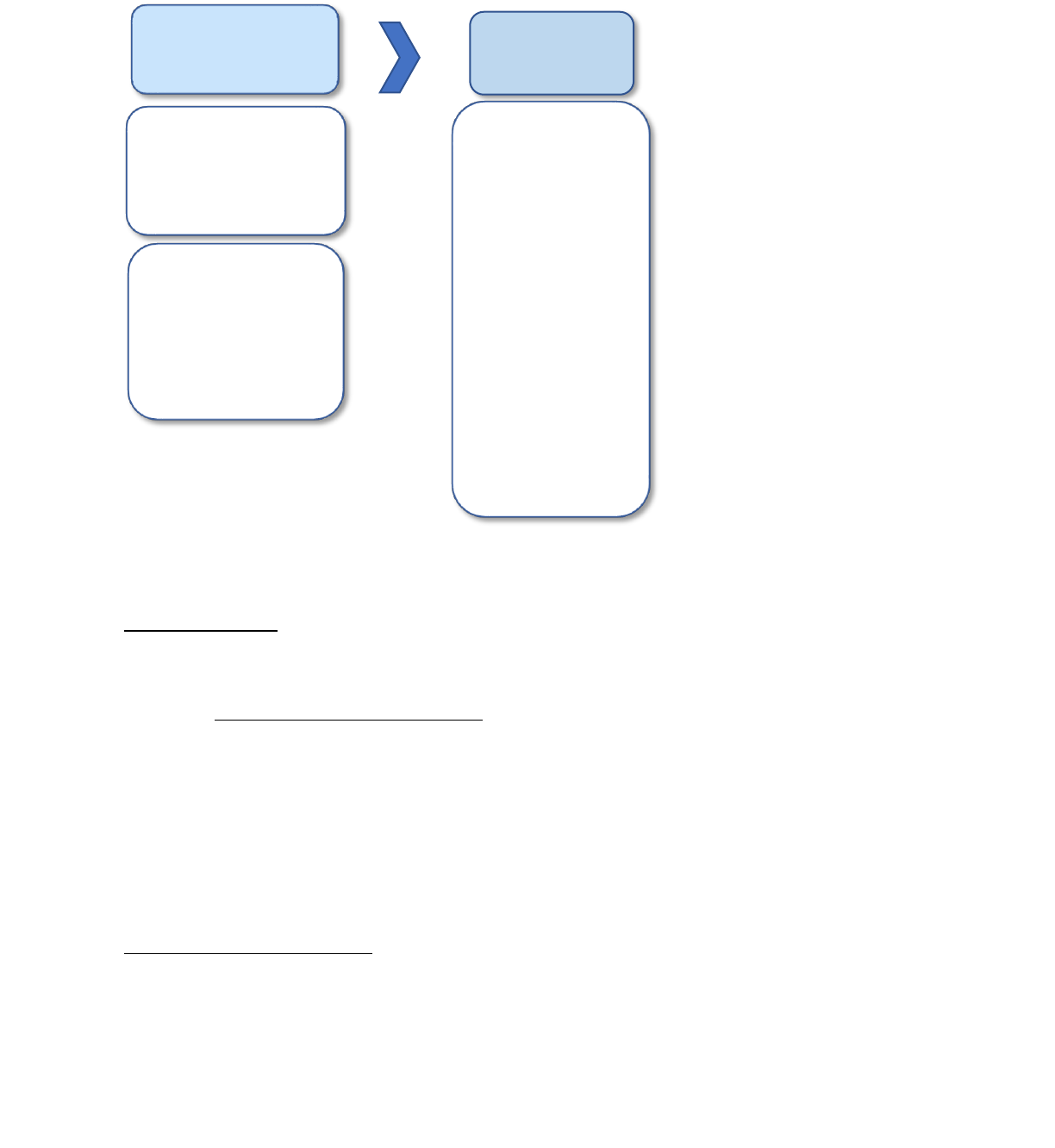

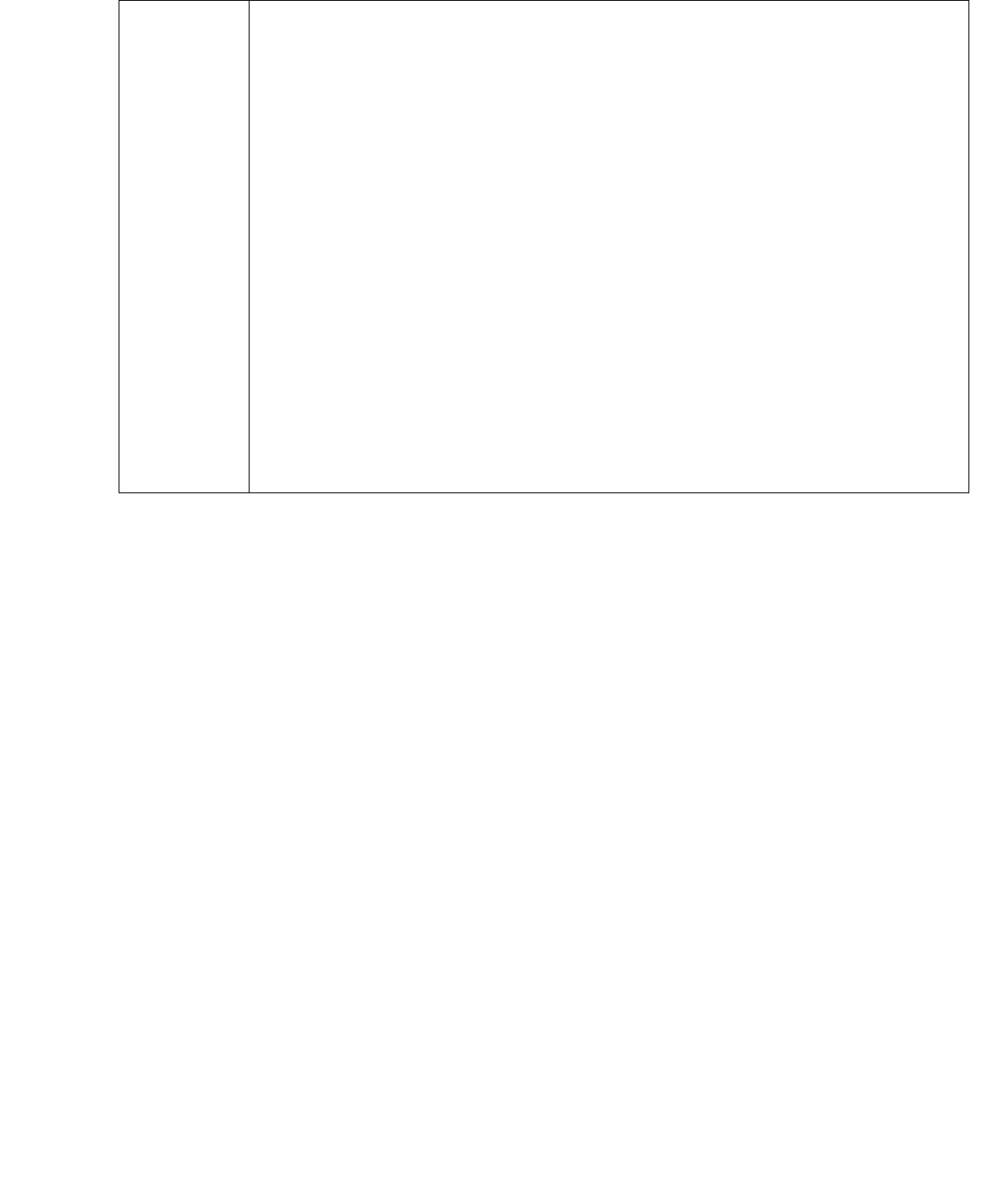

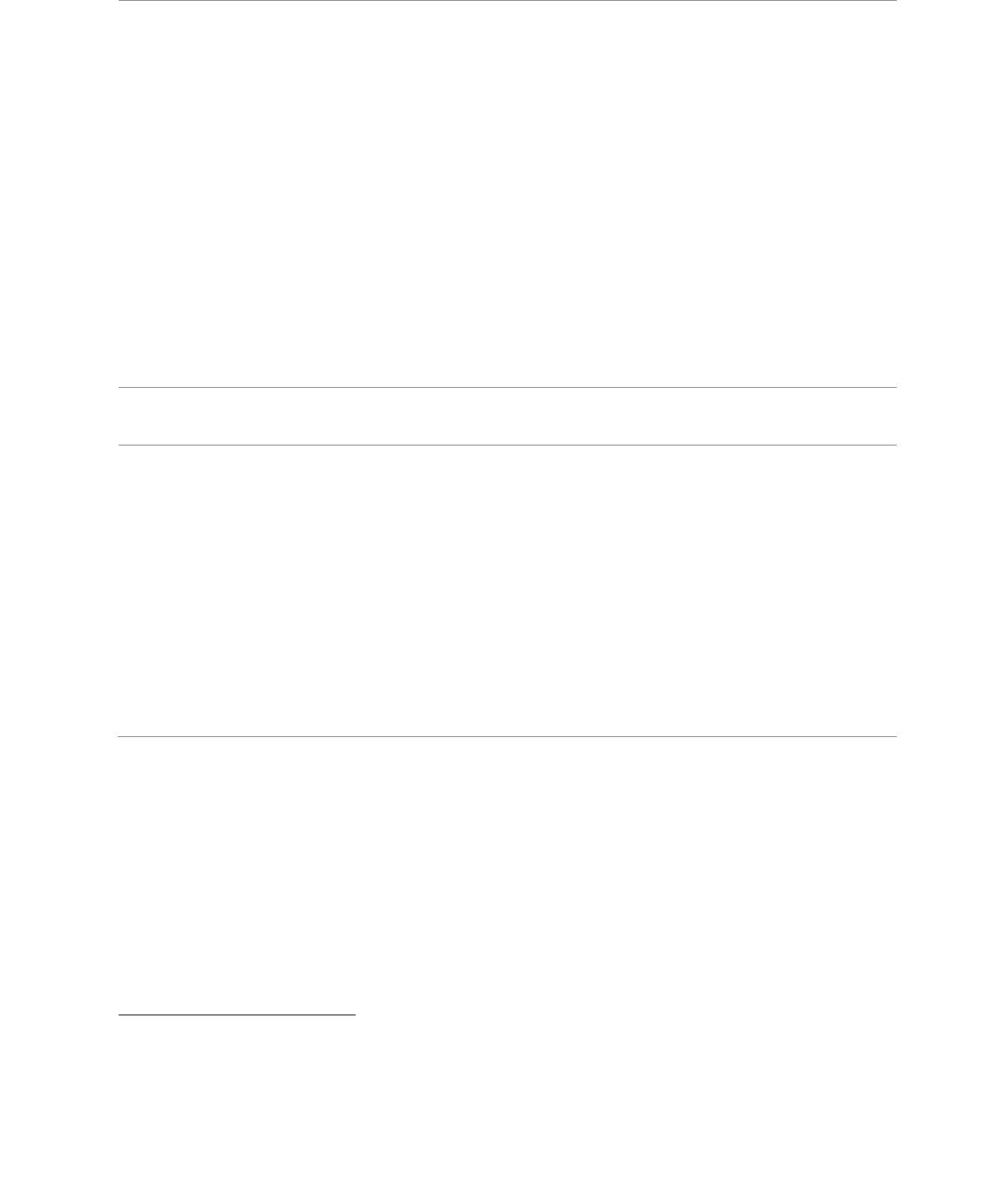

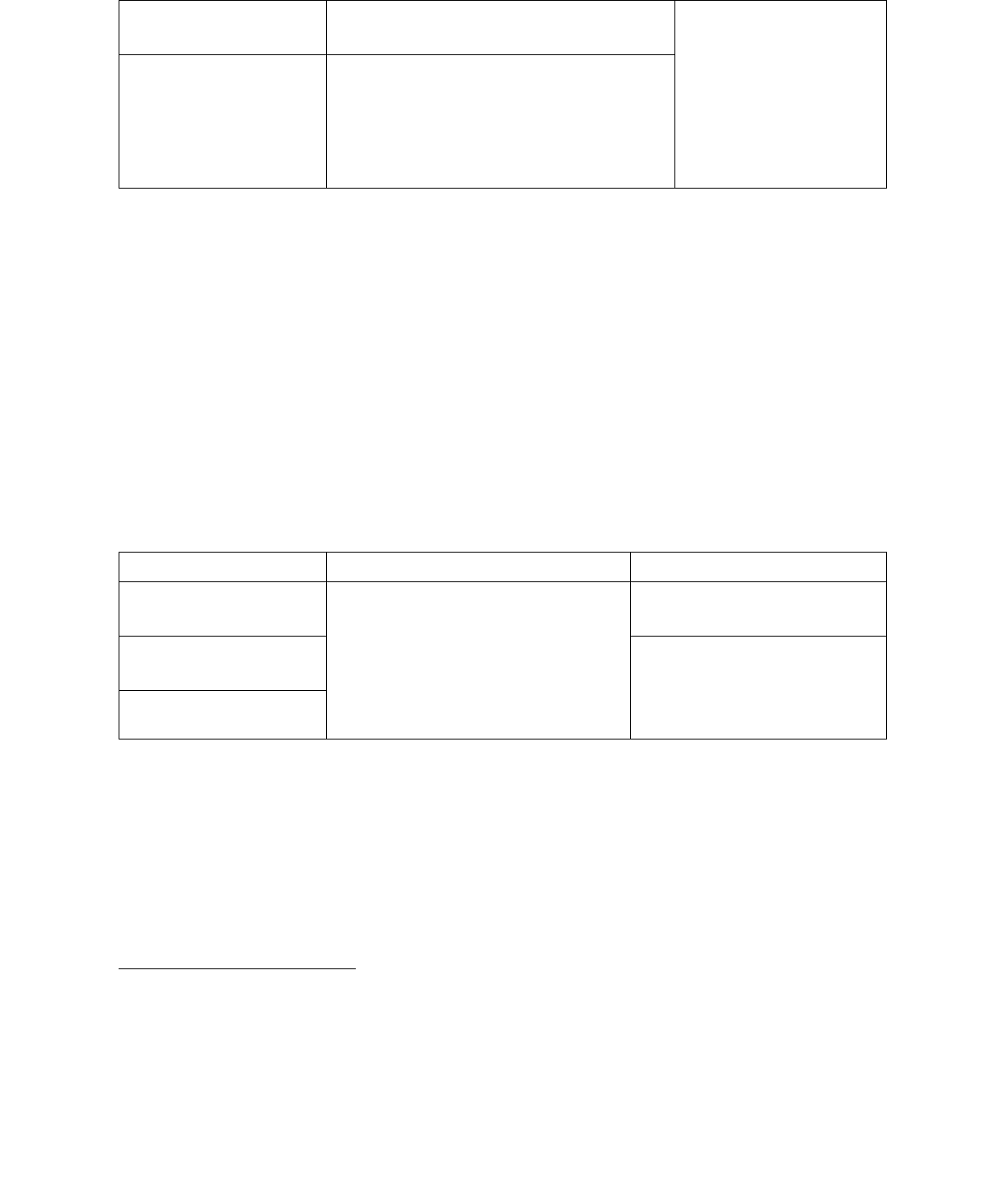

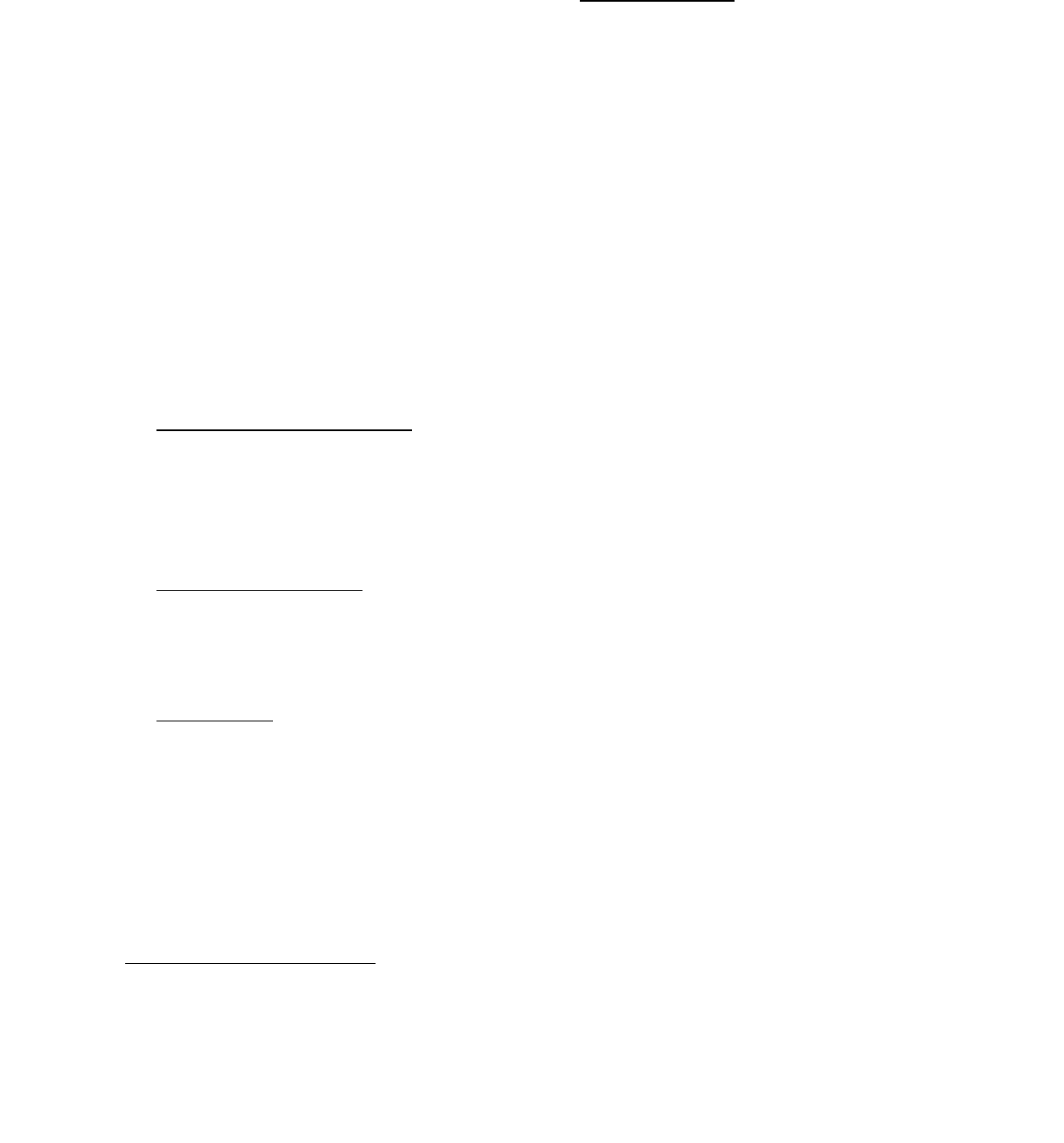

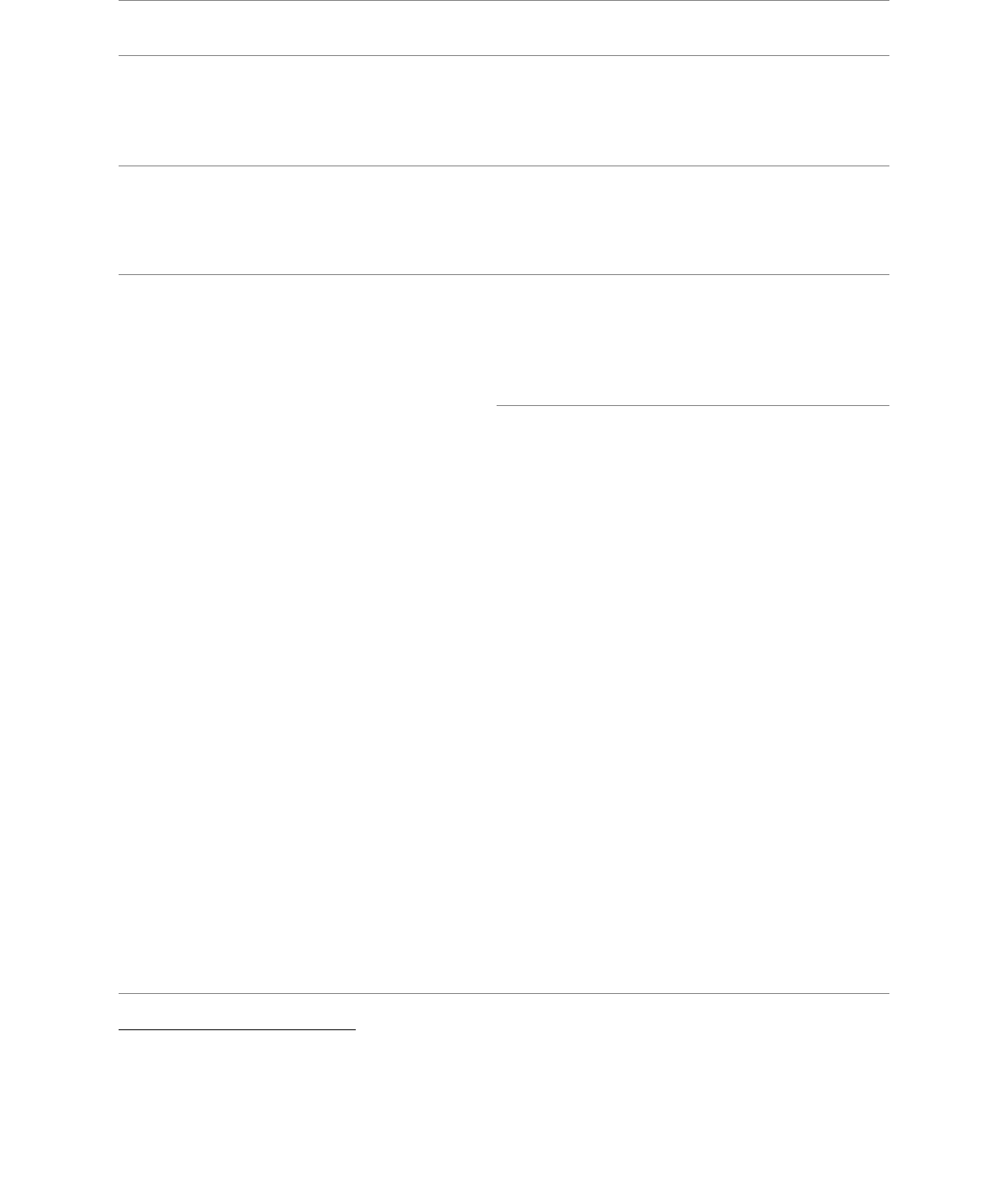

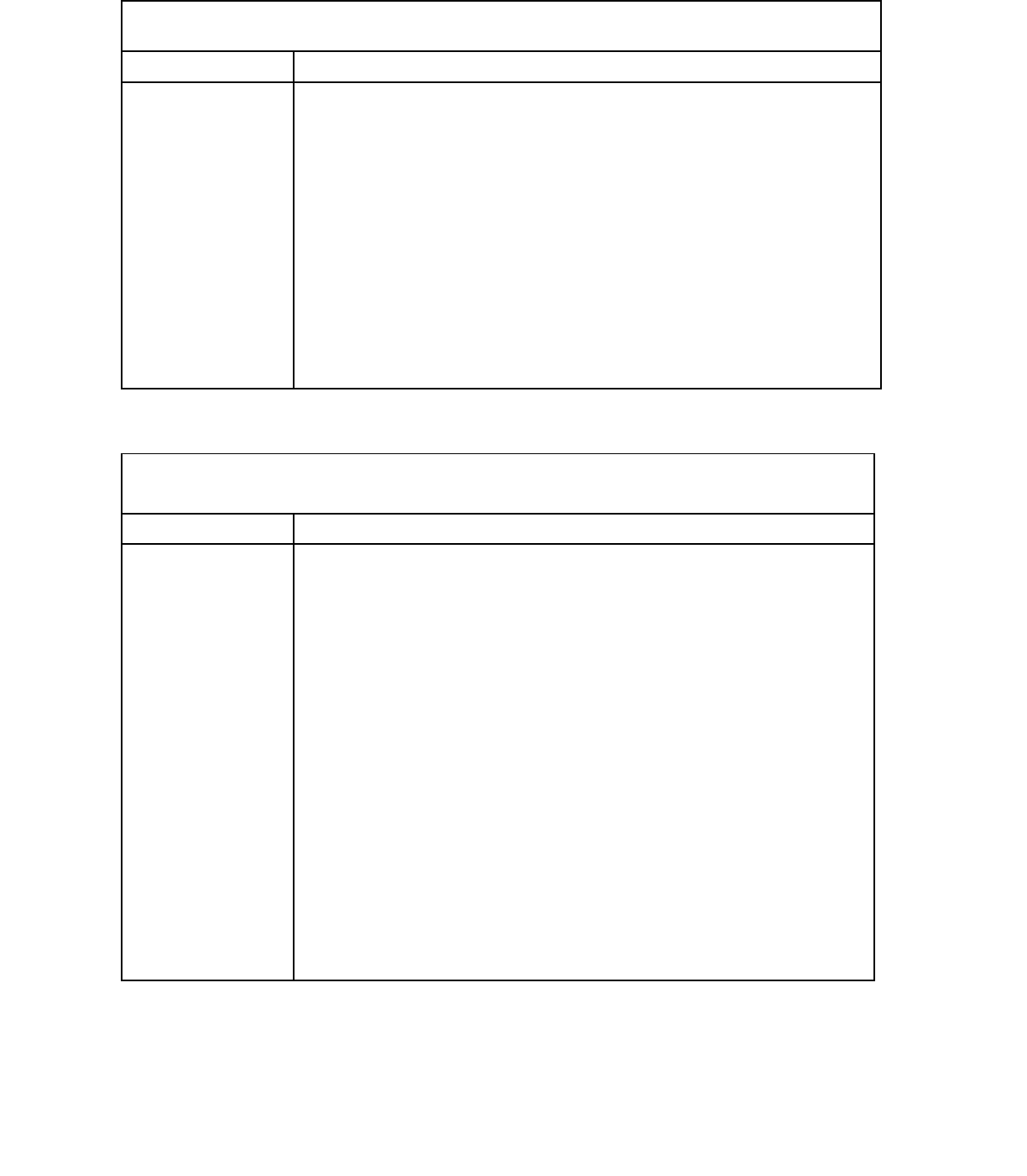

Figure 2.1.1b: Two-Step Application Process

2.1.1.1 Application Submissions

All SGIP applications and required documents

5

are submitted via the SGIP online application database at

www.selfgenca.com. To submit an application and/or project documentation, companies or individuals

must create an Applicant Account and register any anticipated users. All Applicants and Applicant

Administrators must also agree to the SGIP online application database Terms of Use. Terms of Use can

be found at www.selfgenca.com/terms_of_use/. Mailed, emailed, faxed, or hand delivered

applications will not be accepted.

Only complete applications may be assigned incentive funds or be placed into a lottery. Only complete

applications may receive an approved reservation. Duplicate applications or multiple submissions for the

same project are not allowed and will be rejected.

6

5

With the exception of the application fee check that is to be mailed directly to the Program Administrator. See Section 8.1 for more

information.

6

Duplicate applications are considered a program infraction. See Section 13 for information on program infractions. Definition of

project can be found in Definitions and Glossary.

Reservation

Request Form

(RRF)

Incentive

Claim Form

(ICF)

Submit Reservation

Request Form

Submit completed RRF to

Program Administrator.

(See Section 8.1)

Submit Incentive

Claim Form

Submit ICF to

Program

Administrator once

the system is

installed,

interconnected, and

operational. Due no

later than 12 months

from receipt of the

Confirmed

Reservation Letter.

Program

Administrator may

schedule a site

inspection. Upon

approval, the

incentive payment

process begins.

(See Section 7.3)

Receive Conditional

Reservation Letter

Upon approval the

Program Administrator

will issue a Confirmed

Reservation Letter.

(See Section 8.3)

13

2.1.1.1.1 Residential Storage “Soft Target”

The Residential Storage Soft Target reserves 50% of the Step 6 and Step 7 general market small

residential budget for:

• Residential customers living in Tier 3 or Tier 2 High Fire Threat Districts (HFTDs); and/or

• Residential customers whose electricity has been turned off during two or more discrete Public

Safety Power Shutoff (PSPS) events; and/or

• Residential customers who have experienced one PSPS event and one de-energization or power

outage from an actual wildfire that occurred on or after January 1, 2017.

Acceptance of Step 6 and Step 7 general market residential incentive budget applications that do not

meet the criteria outlined above will be paused after such applications reach 50% of the total budget for

each residential incentive step. Acceptance of applications will resume if applications that do not meet the

above criteria drop below 50% of the funding in that budget step.

2.1.1.1.2 Developer Caps

Any single Developer is limited to 20% of the SGIP incentive funding for a given general market budget

category in each statewide incentive step. The Developer Cap will be calculated separately for the

Generation Budget, Large Scale Energy Storage Budget, and Small Residential Energy Storage Budget.

Applicants may not submit applications for Developers in excess of the statewide Developer Cap for the

active step, and Program Administrators shall not issue reservations to projects by a Developer that has

already applied for reservations in a given step that exceed 20%. The Developer Cap will be established

by budget step and posted prior to program opening. The Developer Cap will remain fixed for each

budget step once the step is opened even if the total available funds change.

7

Please see Section 3.6 for

the definition of a Developer.

The Equity and Equity Resiliency Budgets are exempt from the Developer Cap.

2.1.1.1.3 Lottery Process

A lottery will be triggered when applications submitted on a single day exceed funds available for a given

budget and step that is not already on a waitlist.

8

Lotteries are to be conducted separately for each

budget category within a PA’s territory. Any application not selected in a lottery for a specific budget step

will be rejected and must reapply in the next funding step to receive funding. If a lottery is triggered in the

final step of a budget, projects not selected in the lottery will be placed onto the waitlist in the order in

which they were submitted to the application portal.

7

If an incentive step is open at least 12 months and at least two entities have reached their cap and there is otherwise low

participation in the incentive step, the PAs will request modification or suspension to the Developer Cap via Advice Letter.

8

When additional funding is provided in a given budget category, applications on a waitlist will be awarded funding in the order they

were received. No lottery is conducted for waitlist applications.

14

Priority Projects for Lottery

The following energy storage projects shall have priority in the SGIP lottery process:

• Energy storage projects located within the service territory of Los Angeles Department of Water

and Power (LADWP)

9

• Energy storage projects located within the West Los Angeles Local Reliability Area of Southern

California Edison’s service territory

• Energy storage systems paired with an on-site renewable generator and claiming the Investment

Tax Credit (ITC) or, if not claiming the ITC, charging a minimum of 75% from the on-site renewable

generator

Energy storage projects that meet more than one criterion shall be given the highest priority.

Generation projects shall have priority in the SGIP lottery in the following order:

1) Renewable projects using wind, waste heat to power, pressure reduction turbines, or 100% on-

site biogas will be given first priority.

2) 100% directed biogas will be given second priority.

2.1.1.1.4 Pause Periods

When a budget category changes to the next incentive step, the Program Administrator will initiate a

pause period of no less than 20 days. During a pause period the following will occur:

• No new applications within the budget category are accepted.

• The Program Administrator may perform a pre-screen to reject applications with missing

documentation or applications submitted above the Developer Cap, and verify projects identified

with a locational priority.

• After 10 days, Program Administrators will determine if the incentive level reduction for energy

storage technologies shall increase from $0.05/Wh to $0.10/Wh between incentive steps based

on statewide oversubscription for a given step.

• Notification of lottery results will be sent to Applicants. Applications not selected during the lottery

process will be instructed how to reapply for funding in the next step.

• Projects that are only able to be partially funded within a certain step must choose to reapply for

funding in the next step or claim the remaining funds in the current step.

10

• www.selfgenca.com is updated with information on the new incentive rate(s), available funds, and

the date of the next application submission opportunity.

9

All projects interconnecting into LADWP’s electrical grid must abide by LADWP interconnection rules.

10

Projects are not allowed to be assigned a “split incentive” across two or more incentive steps.

15

2.1.1.1.5 Waitlists

Once funds have been fully allocated in the final incentive step of a Program Administrator’s given

budget, applications will be placed on a waitlist in the order in which they were submitted to be funded as

incentive funds become available. When there is enough attrition to fund waitlisted projects, those

projects will be assigned an incentive rate in the last step and reviewed in the order in which they were

submitted. In the event there are available funds and all waitlisted projects have been allocated funding,

new applications will be accepted and subject to standard program procedures (see Section 2.1).

2.1.1.2 Incomplete Applications

If an application is found to be missing any required information or requires additional clarification, the

Program Administrator or their representative will send an email to the Applicant requesting clarification

and/or submission of missing information. Applicants have 15 calendar days to respond with the

requested information for the Reservation Request Form and Proof of Project Milestone. Applicants have

30 calendar days to respond with the requested information for the Incentive Claim Form. If after that time

the Applicant has not submitted the requested information or satisfied the eligibility requirement in

question, the application may be cancelled. An application may not receive multiple

11

requests for the

same missing or uncorrected item(s). Cancelled applications may reapply if funding is available and will

be treated as a new application (i.e., all required documents must be resubmitted) and will be processed

in sequence. Funds from cancelled projects will be reallocated to the currently active incentive step in the

Program Administrator’s SGIP incentive budget. If the Program Administrator is in a pause period when

attrition occurs, the funds will be placed in the next incentive step.

2.1.1.3 Post-Installation Inspections

Upon receipt of a complete Incentive Claim Form package, the project may be selected for an on-site,

post-installation inspection (or virtual inspection for select residential applications)

12

to verify that the

incentivized system is installed as represented in the application, operational, interconnected, and

conforms to the eligibility criteria of the SGIP.

Prior to inspection, energy storage systems must be tested to validate the discharge energy capacity.

HVAC-integrated S-TES systems must be tested to show their ability to provide enough thermal energy to

turn off the compressor of the accompanying HVAC unit for the specified discharge duration period.

Refrigeration TES systems must be tested to show their ability to provide enough thermal energy to turn

off the compressor(s) and condenser(s) of the accompanying refrigeration system(s) for the specified

discharge duration period. L-TES systems must be tested to show their ability to provide enough thermal

energy to turn off the compressor of the accompanying chiller unit for the specified discharge duration

11

Number of request for clarification/missing information emails allowed is up to the discretion of the Program Administrator.

12

Refer to Energy Storage Field Inspection and Discharge Testing Protocol and Field Inspection Sampling Protocol at

www.selfgenca.com.

16

period. This data is provided by the Developer at the Incentive Claim Form stage once the project has

been selected for inspection.

On-site verification includes, but is not limited to:

• For all systems, the inspection will verify the system capacity rating to support the final incentive

value.

• If the project is subject to PBI payments, the metering system will be inspected, and it will be

verified that it follows the proposed monitoring plan and meets the metering requirements of the

SGIP.

• If the project uses renewable fuel, the availability and flow rate of the renewable fuel will be

demonstrated by the Host Customer and/or System Owner.

• If the project uses waste energy, the availability, temperature, and production rate of the waste

energy will be demonstrated by Host Customer and/or System Owner.

• Energy storage projects will be inspected according to the Energy Storage Field Verification

Protocol. Generation projects will be inspected according to the Generation System Inspection

Protocol. The latest versions of the inspection protocols can be found on www.selfgenca.com/.

Failed Post-Installation Inspection

If the results of the inspection indicate that the project cannot be approved, the Program Administrator will

notify the Applicant, Host Customer, and System Owner of the reasons for failure. The Applicant, Host

Customer, and System Owner will have up to 60 calendar days to bring the project into compliance and a

subsequent inspection visit may be required to determine final approval. If the Applicant, Host Customer,

and System Owner fail to bring the project to compliance within the requested time, the application may

be cancelled.

If the site load, availability of renewable fuel, or waste energy forecast has not yet materialized, the

Applicant will be given two options:

1. Receive payment based on the site load, renewable fuel, or waste energy availability (whichever

is less) demonstrated at the time of initial inspection.

2. Wait for the site load, renewable fuel, or waste energy to materialize within 12 months from the

date the Incentive Claim Form and documents were initially received. If the site load, renewable

fuel, or waste energy has not materialized within the 12-month period, the project will be paid

based on the site load or system operating capacity available at the end of the 12-month period,

whichever is less.

2.1.2 Application/Project Modifications, Extensions and Cancellations

All projects are expected to be installed as described on the Conditional and Confirmed Reservation

Letter. If changes are made during the development of the project and/or during the installation, it is the

responsibility of the Host Customer and/or Applicant to notify the Program Administrator as soon as

17

possible. Changes to the Host Customer or project site location are generally not permitted and must be

approved on a case-by-case basis by the Program Administrator. Unapproved changes may result in

project cancellation.

Modifications Pre-ICF

Changes pertaining to program participants (Applicant, System Owner, Developer, Payee, Installer),

equipment type, fuel type, system capacity, or incentive step-down structure must be approved by the

Program Administrator before the application can proceed. If the step to which a project is assigned has

closed, modifications to the project will not result in additional incentive funding. At the Program

Administrator’s discretion, changes to an application resulting in additional incentive funding may be

allowed only when a project is assigned to the active step and adequate funding is available.

Changes in equipment type, fuel type, system capacity, program participants (Applicant, System Owner,

Developer, Payee, Installer), or other substantial changes may require the execution of a new RRF and/or

PPM along with additional documentation. Once the request has been approved, a new reservation letter

may be issued. Any such changes do not extend the reservation expiration date.

Modifications Post-ICF

In general, changes to completed projects are not allowed. If a system needs to be upgraded or changed

due to poor performance, the Applicant must notify the Program Administrator of new equipment

information and provide updated documentation to help support performance and measurement and

evaluation activities. For system replacements, see Section 4.5.5.

If there is a change in ownership of the property which hosts the SGIP equipment, the new owner may

continue to receive the remaining PBI if the new owner completes a new interconnection agreement.

However, if the original Host Customer relocates the equipment, they may continue to receive the PBI

incentive payments if the equipment is relocated within the same Program Administrator’s service territory

within six months and the System Owner completes an interconnection agreement at the new address. In

either case, the PBI payment sunset date will not be extended.

Extensions and Exceptions

Extension requests will be reviewed on a case-by-case basis and should be submitted in writing to the

appropriate Program Administrator for review. Any extension granted to either the Proof of Project

Milestone or Request for Proposal due date will not extend the reservation expiration date.

All projects will be limited to a maximum of three six-month extensions of the reservation expiration date,

after which the reservation expires automatically.

13

Extensions will be for special circumstances only and

will not be granted to projects that have not made progress toward project completion. Any request for a

second or third extension of the reservation expiration date requires unanimous SGIP Working Group

approval, and the SGIP Working Group shall notify Applicants of the decision in writing within 30 days.

13

D.15-06-002 granted a petition for modification to increase the number of six-month extensions from two to three.

18

When considering a request for a second or third reservation expiration date extension, the SGIP

Working Group will consider:

1. Whether the project’s delay is outside the control of the Host Customer.

2. Whether the project has made significant progress toward completion, and a timeline is provided

showing the expected date of commissioning of the project and that interconnection of the project

will fall within the third six-month extension of the project’s reservation expiration date.

3. Whether the extension of the project’s reservation expiration date will affect the Program

Administrator’s ability to incentivize other projects.

Wind Turbine Project Extensions:

The reservation expiration date for any project using wind turbines shall be automatically extended for the

period of time the Applicant is awaiting a final non-appealable decision on a permit required for the

installation and operation of such project or the utility’s completion of any interconnection upgrades (i.e.,

interconnection facilities, distribution upgrades, and network upgrades). To administer this provision, upon

the Program Administrator’s request, the Applicant shall provide the Program Administrator with evidence

satisfactory to the Program Administrator of (a) the date on which the Applicant filed its application for

such permit, (b) the date on which the submitted interconnection application was submitted, (c) the date

on which a final non-appealable decision on such permit has been issued, and (d) the date on which the

utility has completed construction of any required upgrades.

14

Stay on Cancellations due to COVID-19 pandemic:

15

Projects that have exhausted the maximum of three six-month extensions and require additional time to

complete the installation due to issues related to the COVID-19 pandemic may be granted a stay on the

cancellation not to exceed one year from the project’s Reservation Expiration Date. Program

participants seeking additional time due to COVID-19 delays must submit a written request with

verifiable information that clearly demonstrates the project was progressing in a timely manner prior to

the COVID-19 pandemic. Similar to a second or third extension request, any request for a stay of

cancellation requires unanimous SGIP Working Group approval, and the SGIP Working Group shall

notify Applicants within 30 days of a submitted request. When considering a request for a stay of

cancellation, the SGIP Working Group will consider:

1. Whether the project’s delay is due to COVID-19 related impacts and was outside the control of

the Host Customer.

• Review is to include documentation (provided as part of the formal request) to substantiate

the specific COVID-19 related restrictions and/or impacts that prohibited the completed

installation of the project.

14

No wind project will be suspended beyond June 30, 2027 unless the Legislature authorizes additional revenue collections for

SGIP purposes such that the SGIP’s sunset date is extended beyond the date of January 1, 2026 authorized in Senate Bill 700.

15

Pursuant to D.21-03-009

19

2. Whether the project has made significant progress toward completion and would otherwise have

been installed prior to the current reservation expiration date.

• Review is to include a revised timeline (provided as part of the formal request) showing the

expected date of commissioning of the project and that interconnection of the project will be

no greater than one year from the project’s reservation expiration date.

PBI Pause on Calculations due to COVID-19:

Projects not able to meet the performance obligations of the program due to COVID-19 restrictions may

request to have their PBI calculations paused for no longer than one year. A written request must be

provided to the Program Administrator with verifiable justification that demonstrates the customer is

unable to meet the PBI requirements due to COVID-19 related issues. Program Administrator exception

review will include:

1. Whether system performance is due to COVID-19 related impacts and was outside the control

of the Host Customer.

• Review is to include documentation (provided as part of the formal request) to substantiate

the specific COVID-19 related restrictions and/or impacts that prohibited the performance

obligations of the system.

2. A revised timeline (provided as part of the formal request) showing the pause period (no greater

than one year) being requested and plan to re-establish the performance obligations of the

system.

If the request is approved, the project’s performance period will be extended by the number of months

that the PBI period was paused to ensure performance obligations are met prior to full payment.

Any other procedure or documentation exceptions should be submitted to the appropriate Program

Administrator and will be subject to Working Group approval.

Developer Declares Bankruptcy or Otherwise Goes Out of Business

A reserved project that has been installed but unable to complete the required outstanding

documentation (i.e., PTO, Final Monitoring Schematic) because the Developer has declared bankruptcy

or otherwise gone out of business, a Host Customer or Applicant may request an additional 90-day

extension. A request for a 90-day extension shall require unanimous SGIP Working Group approval.

16

Note: These projects will also require an exception to the service warranty and fleet GHG compliance

enforcement actions which requires CPUC approval through the disposition of a Tier 2 Advice Letter

submitted by the PAs.

16

For projects that are already beyond their 90-day extension in addition to the three six-month extensions, the additional 90-day

extension commences with the disposition date of the PA-filed Tier 2 Advice Letter allowing for such an extension.

20

3 Program Participant Eligibility

3.1 Host Customer

To receive the SGIP incentives, the Host Customer must be a retail electric or gas distribution class of

customer (industrial, agricultural, commercial, or residential) of PG&E, SCE, SoCalGas, or SDG&E.

17

Additionally, to receive the SGIP incentive, the Host Customer is required to be the utility customer of

record at the site where the SGIP system is to be located. If the Host Customer’s name is not on the utility

bill, a letter of explanation is required to address the relationship of the Host Customer to the utility

customer of record. If the Host Customer is renting the property, a letter of explanation is required to

address the relationship and approval from the homeowner to the tenant.

The Host Customer is the exclusive incentive reservation holder who is party to the SGIP Contract

(accessible at https://www.selfgenca.com/home/resources/). The Host Customer has the authority to

designate the Applicant, System Owner (if not Host Customer), and/ or Developer and change any of

these parties at any time.

For multifamily buildings that are installing a system on behalf of tenants and are enrolled in a Virtual Net

Energy Metering (VNEM) tariff, the Property Owner may be the Host Customer.

3.2 Host Customer Eligibility for the Equity, Equity Resiliency, and San Joaquin

Valley Budgets

3.2.1 Residential Equity Eligibility

For the Equity Budget, residential projects are classified as either multifamily low-income housing or

single-family low-income housing. GHG emission standards, operating requirements, and incentive

payment structure for multifamily projects will be determined by the project’s “primary use” as defined in

Section 3.3.

Multifamily

Multifamily residential customers applying for the Equity funding must comply with a specified pathway

under both Criteria 1 and 2 or Criteria 3:

17

“…retail electric or gas distribution class of customer…” means that the Host Customer pays for and receives distribution services,

as defined by their respective utility rate schedule.

21

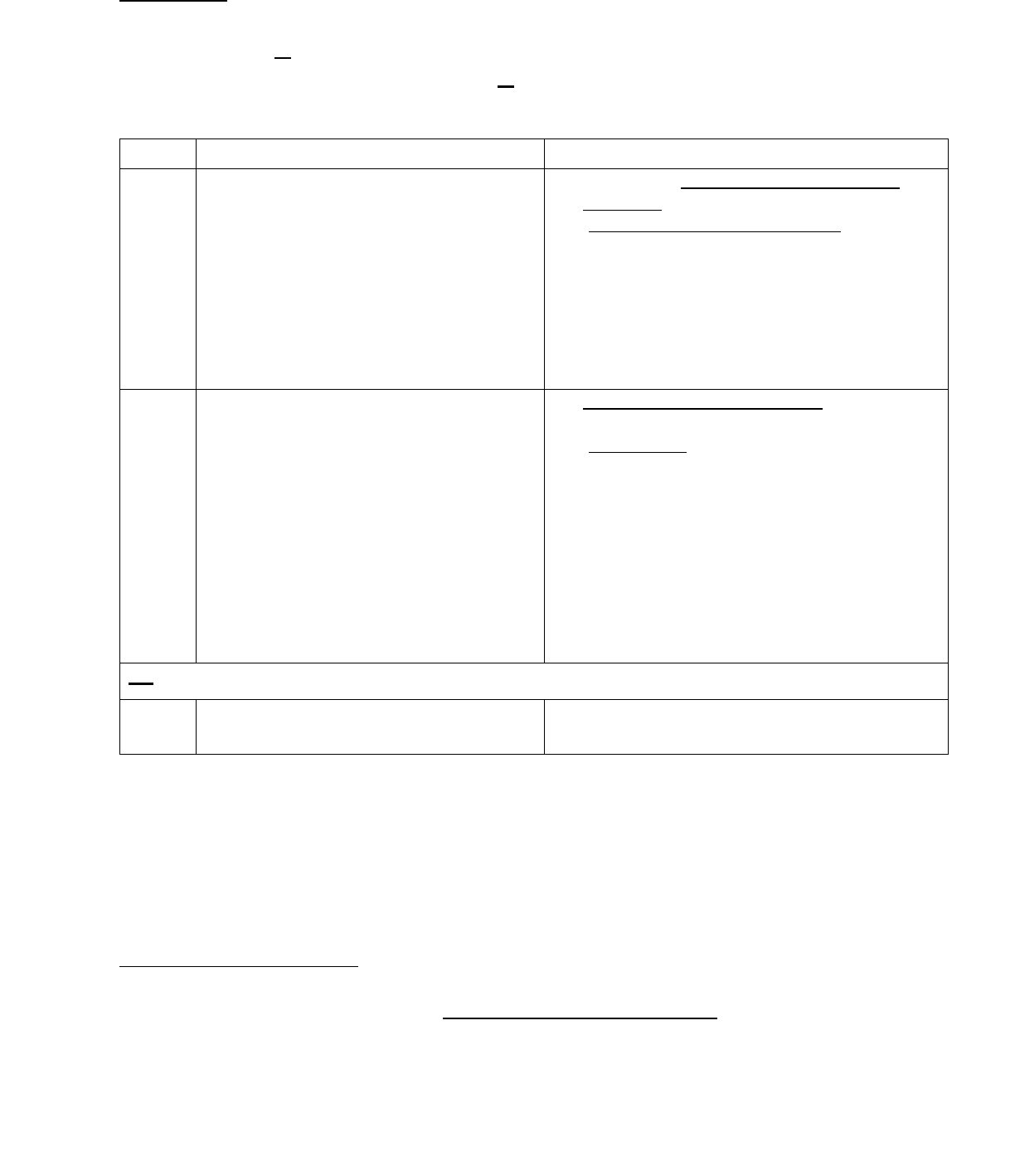

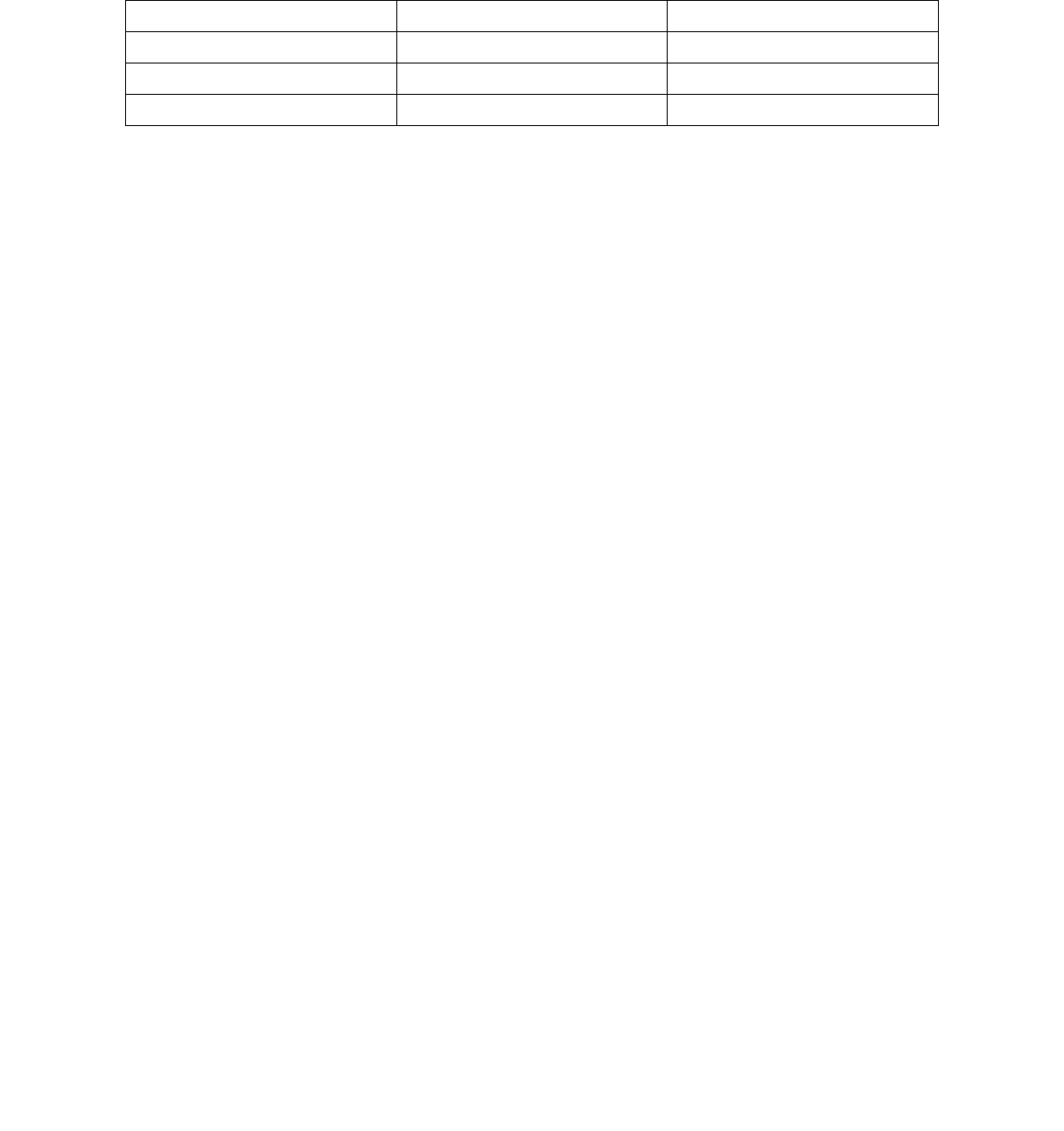

Table 3.2.1a: Pathways for Eligibility, Multifamily

Criteria

Pathways for Eligibility

Additional Guidance

1

Multifamily residential building of at least

five rental housing units that is operated to

provide deed-restricted low-income

residential housing.

18

2

a) Located in a disadvantaged

community

19

(including Indian

Country

20

); or

• CalEnviroScreen SB 535 Disadvantaged

Communities Map

(oehha.ca.gov/calenviroscreen/sb535)

• Non-Indian multifamily residences on privately

owned fee land in Indian Country are not eligible

under this expanded definition. If the in-holding has

multiple owners, at least one owner must be a tribe

or tribal member for the project to be eligible.

b) Is a building where at least 80% of the

households have incomes at or below

60% of the area median income.

21

Any

customer account in such buildings will

be eligible for the Equity Budget.

• Housing and Urban Development’s Income

Guidelines for verifying area median income

(huduser.gov/portal/datasets/il.html)

OR

3

Have reserved funds in the MASH or

SOMAH programs.

18

As described in clause (i) of subparagraph (A) of paragraph (3) of subdivision (a) of § 2852 of the Public Utilities Code.

19

Definition of “disadvantaged community” can be found in Definitions and Glossary section at end of Handbook.

20

As defined in 18 USC §1151.

21

As defined in subdivision (f) of § 50052.5 of the Health and Safety Code.

22

Single-Family

Single-family low-income residential customers applying for the Equity Budget funding must comply with

both Criteria 1 and 2 or Criteria 3. Single-family low-income residences in California Indian Country are

eligible for the Equity Budget if they meet Criteria 1 or Criteria 3.

Table 3.2.1b: Pathways for Eligibility, Single Family

Criteria

Pathways for Eligibility

Additional Guidance

1

Income verification

22

(see Section 8.1 item

#9 for more information); and

• Housing and Urban Development’s Income

Guidelines for verifying area median income

(huduser.gov/portal/datasets/il.html)

• Non-Indian residences on privately owned fee

land in Indian Country are not eligible under this

expanded definition. If the in-holding has

multiple owners, at least one owner must be a

tribe or tribal member for the project to be

eligible.

2

A resale restriction

23

or an equity sharing

agreement, for which the homeowner does

not receive a greater share of equity than

described in paragraph (2) of subdivision (c)

of Section 65915 of the Government Code,

with a public entity or nonprofit housing

provider organized under Section 501(c)(3)

of the Internal Revenue Code that has as its

stated purpose in its articles of incorporation

on file with the office of the Secretary of

State to provide affordable housing to lower

income households.

24

• CPUC Residential Eligibility Map for census

tracts with a presumed resale restriction

(arcg.is/KLqr1)

OR

3

Have reserved funds in the SASH or DAC-

SASH programs.

22

Documentation showing the Host Customer’s household income is 80% of the area median income or less based upon a copy of

the most recently available federal income tax documentation. Area Median Income is subject to annual changes based upon

Housing and Urban Development's income guidelines (https://www.huduser.gov/portal/datasets/il.html).

23

Certain and specific “presumed resale restrictions” meet this requirement. See Section 8.1 for more information.

24

Subparagraph (c) of paragraph (3) of subdivision (a) of § 2852 of the Public Utilities Code.

23

3.2.2 Non-Residential Equity Eligibility

Non-residential customers applying for the Equity Budget funding must comply with a specified pathway

under Criteria 1 and Criteria 2. Multi-tenant commercial building customers may only submit applications

to the General Market Budgets. Such customers are not eligible for Equity or Equity Resiliency incentives.

Table 3.2.2: Pathways for Eligibility, Non-Residential

Criteria

Pathways for Eligibility

Additional Guidance

1

a) State

or Local Governmental Agency

b) Tribal Government Agency

• Non-Indian businesses on privately owned fee

land in Indian Country are not eligible under this

expanded definition. If the in-holding has multiple

owners, at least one owner must be a tribe or

tribal member for the project to be eligible.

c) Educational Institution

d) Non-Profit

e) Small Business

2

a) Project site is located in a

disadvantaged, tribal, or low-income

community, or demonstrates that at

least 50% of the census tracts it

serves are disadvantaged, tribal, or

low-income communities; or

• CalEnviroScreen SB 535 Disadvantaged

Communities Map

(oehha.ca.gov/calenviroscreen/sb535)

• CPUC Non-Residential Eligibility Map for

Disadvantaged, Tribal, and Low-Income

Communities. (arcg.is/0vn19T)

b) Any facility owned or operated by a

public agency that provides services

to DAC or low-income community

members for which at least 50% of

census tracts served are DACs or

low-income communities.

24

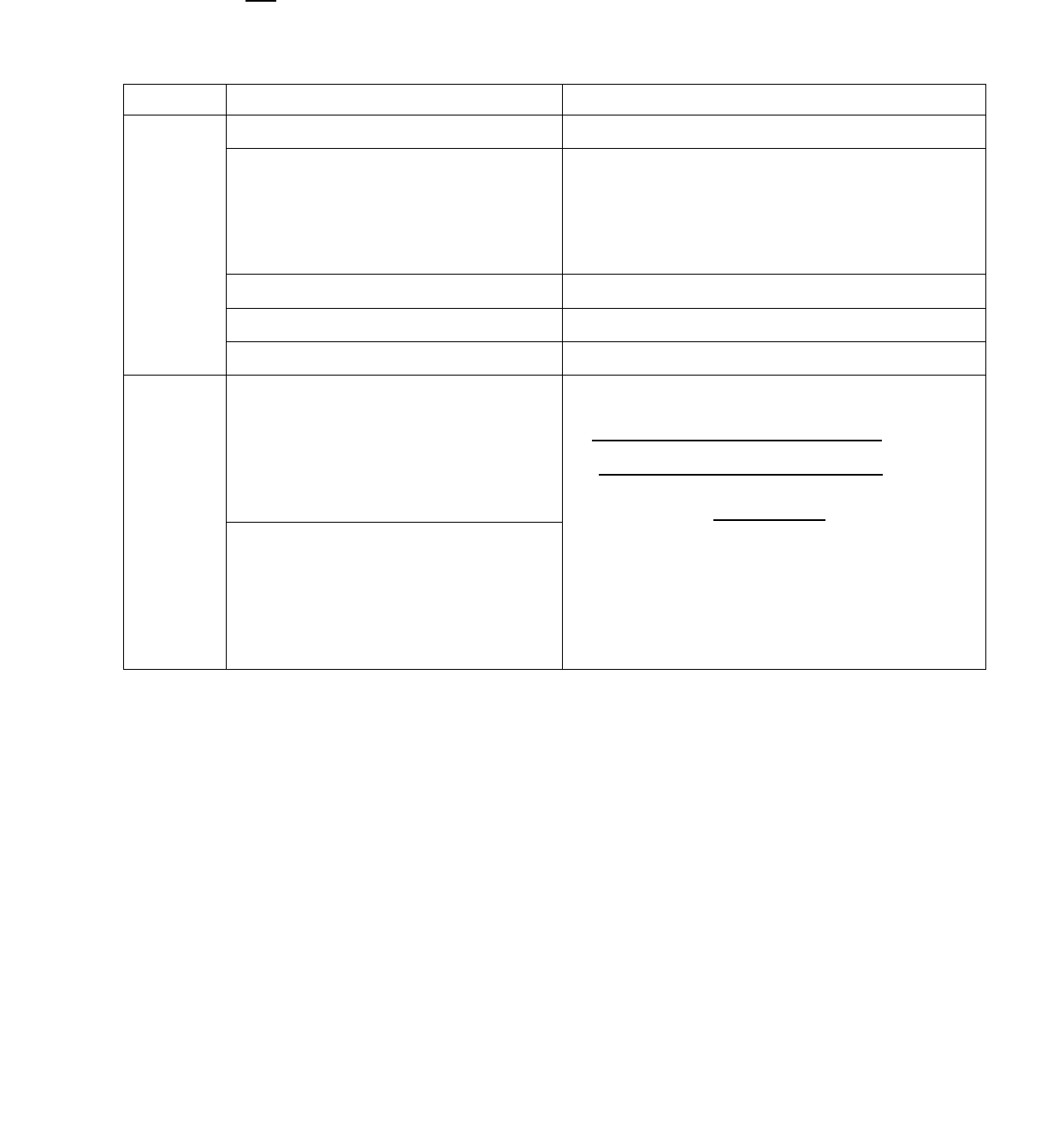

3.2.3 Residential Equity Resiliency Eligibility

Residential customers (single family or multifamily) applying for the Equity Resiliency Budget funding

must comply with a specified pathway under both Criteria 1 and Criteria 2:

Table 3.2.3: Pathways for Eligibility, Residential Equity Resiliency

Criteria

Pathways for Eligibility

Additional Guidance

1

Project site is located in a Tier 3 or Tier 2

High Fire Threat District (HFTD); or

CPUC Fire Map available here:

(https://capuc.maps.arcgis.com/apps/webappviewer/ind

ex.html?id=5bdb921d747a46929d9f00dbdb6d0fa2)

Customers whose electricity was shut off

during two or more discrete Public Safety

Power Shutoff (PSPS) events prior to

date of application for SGIP incentives;

or

• List of circuits with two or more PSPS events

posted on the SGIP portal.

25

• PG&E PSPS Lookup Tool

(https://www.pge.com/en_US/safety/emergency-

preparedness/natural-disaster/wildfires/psps-event-

lookup.page)

• CSE PSPS Wildfire Event Lookup Tool

(sgipsd.org/event-look-up)

• SCE PSPS Lookup Tool

(https://www.sce.com/residential/generating-your-

own-power/incentive-program/psps-sgip)

Customers whose electricity was shut off

during one discrete PSPS event and one

de-energization or power outage from an

actual wildfire that occurred on or after

January 1, 2017.

• List of circuits with two or more PSPS events

posted on the SGIP portal.

(https://www.pge.com/en_US/safety/emergency-

preparedness/natural-disaster/wildfires/psps-event-

lookup.page)

• CSE PSPS Wildfire Event Lookup Tool

(sgipsd.org/event-look-up)

• SCE PSPS Lookup Tool

(https://www.sce.com/residential/generating-your-

own-power/incentive-program/psps-sgip)

2

Multifamily or single-family projects

eligible for the Equity Budget; or

• See Section 3.2.1

A resident within the household project

site must be eligible for the Medical

Baseline program; or

The customer has notified their utility of a

serious illness or condition that could

become life-threatening if electricity is

disconnected; or

25

To be updated 30 days after new PSPS event.

25

a) Household relies on electric-pump

wells for water supplies and also

meets the following criteria:

• The residential household

meets the income eligibility

requirements for the Equity

Budget; and

• The project site is a primary

residence occupied by either a

homeowner or tenant; and

• The residence is not provided

water by a municipal or privately-

owned utility.

26

• Housing and Urban Development’s Income

Guidelines for verifying area median income.

(https://www.huduser.gov/portal/datasets/il.html)

3.2.4 Non-Residential Equity Resiliency Eligibility

Non-residential customers applying for Equity Resiliency funding must comply with a specified pathway

under Criteria 1, 2, and 3. Multi-tenant commercial building customers may only submit applications to

the General Market Budgets. Such customers are not eligible for Equity or Equity Resiliency incentives.

Table 3.2.4: Pathways for Eligibility, Non-Residential Equity Resiliency

Criteria

Pathways for Eligibility

Additional Guidance

1

a) Project site is located in a Tier 3

or Tier 2 HFTD; or

• Maps available here:

(https://capuc.maps.arcgis.com/apps/webappviewer

/index.html?id=5bdb921d747a46929d9f00dbdb6d0f

a2)

26

The Electric Well Pump Attestation can be found at www.selfgenca.com/home/resources.

26

b) Customers whose electricity was

shut off during two or more

discrete PSPS events prior to

date of application for SGIP

incentives.

• List of circuits with two or more PSPS events

posted on SGIP portal.

27

• PG&E PSPS Lookup Tool

(https://www.pge.com/en_US/safety/emergency-

preparedness/natural-disaster/wildfires/psps-event-

lookup.page)

• CSE PSPS Wildfire Event Lookup Tool

(sgipsd.org/event-look-up)

• SCE PSPS Lookup Tool

(https://www.sce.com/residential/generating-your-

own-power/incentive-program/psps-sgip)

2

a) Provides critical facilities or

infrastructure to one or more

communities in a Tier 3 or Tier 2

HFTD, a community with

customers whose electricity was

shut off during 2 or more discrete

PSPS events prior to the date of

application for SGIP incentives,

or a community whose electricity

was shut off during one discrete

PSPS event and one de-

energization or power outage

from an actual wildfire that

occurred on or after January 1,

2017; and

b) At least one of those

communities is eligible for the

Equity Budget. Equity Budget

eligible community refers to a

disadvantaged or low-income

community or California Indian

Country. Emergency Feeding

Organizations, homeless

shelters, and independent living

centers are exempt from the

Equity requirement.

28

• CalEnviroScreen SB 535 Disadvantaged

Communities Map

(oehha.ca.gov/calenviroscreen/sb535)

• Priority Populations Map

(https://webmaps.arb.ca.gov/PriorityPopulations/)

• CPUC Non-Residential Eligibility Map

(https://arcg.is/KHX9X)

27

To be updated 30 days after new PSPS event.

28

Non-residential customers with critical resiliency needs do not need to meet eligibility criteria for the SGIP Equity budget

themselves. Non-residential customers with critical resiliency needs are not required to exclusively serve communities that are

located in a Tier 3 or Tier 2 HFTD and are also eligible for the Equity budget.

27

3

Is one of the following critical facilities and infrastructures listed below:

• Police stations

• Fire stations

• Emergency response providers with the addition of tribal government providers

• Emergency operations centers

• 911 call centers (also referred to as Public Safety Answering Points)

• Medical facilities including hospitals, skilled nursing facilities, nursing homes, blood banks,

health care facilities, dialysis centers, and hospice facilities

• Public and private gas, electric, water, wastewater, or flood control facilities

• Jails and prisons

• Locations designated by the IOUs to provide assistance during PSPS events

• Cooling centers designated by state, local or tribal governments

• Homeless shelters supported by federal, state, or local, or tribal governments

• Grocery stores, corner stores, markets, and supermarkets that have average annual gross

receipts of $15 million or less as calculated at the single location applying for SGIP

incentives

• Independent living centers

• Emergency Feeding Organizations

28

3.2.5 San Joaquin Valley Eligibility

Residential

Residential customers applying for San Joaquin Valley (SJV) funding must comply with both Criteria 1

and 2.

Table 3.2.5a: Pathways for Eligibility, Residential San Joaquin Valley

Criteria

Pathways for Eligibility

1

Customer is located in one of the following eligible SJV cities: Allensworth, Alpaugh,

Cantua Creek, Ducor, Fairmead, Lanare, Le Grand, La Vina, Seville, West Goshen, and

California City.

2

Eligibility for the approved residential SJV pilot is limited to households that participate in

the pilot by replacing one or more propane, wood-burning, or inefficient or inoperable

major electric appliances with the efficient electric appliances offered by the pilot.

CARE-eligible and Medical Baseline-eligible SJV pilot households that wish to access SGIP incentives

must enroll in an SGIP-approved rate, if one is available, or in any CARE or Medical Baseline TOU rate if

an SGIP-approved rate is not available, regardless of the date of submittal of the SGIP application.

Non-Residential

Non-residential customers applying for SJV funding must comply with a specified pathway under both

Criteria 1 and 2.

Table 3.2.5b: Pathways for Eligibility, Non-Residential San Joaquin Valley

Criteria

Eligibility

1

Customer is located in one of the following eligible SJV cities: Allensworth, Alpaugh, Cantua

Creek, Ducor, Fairmead, Lanare, Le Grand, La Vina, Seville, West Goshen, and California City.

2

Eligibility for the approved non-residential SJV pilot incentives is one of the following critical

facilities and infrastructure as listed in Criteria 3 under Section 3.2.4.

Both Residential and Non-Residential SJV Pilot customers must adhere to the GHG reduction

requirements.

3.3 Classification of Multifamily Properties

For the purposes of GHG emission standards, operational requirements and incentive payment structure,

the classification of energy storage systems installed at multifamily properties will be determined by the

energy storage system’s primary use.

Virtual Net Energy Metering (VNEM) Projects

29

If the energy storage system is paired with a solar photovoltaic system and interconnects through virtual

net energy metering (VNEM), the primary use will be determined by the VNEM Generation Credit

Allocation Request Form.

If 51% or greater of VNEM credits are allocated to tenant accounts, the energy storage system will be

considered residential, and residential GHG emission standards, operational requirements, and incentive

payment structure will apply. If 50% or greater of VNEM credits are allocated to a common area

account(s), the system’s primary use will be considered “common load”, and the applicable GHG

emission standards, operational requirements and incentive calculation will be determined by the

common meter account’s rate schedule. If the common meter is on a residential rate, the project will be

considered residential and residential GHG emission standards, operational requirements, and incentive

payment structure will apply. If the common meter account is on a non-residential rate, non-residential

GHG emission standards, operational requirements and incentive payment structure will apply.

Non-Virtual Net Energy Metering (VNEM) Projects

If the energy storage system is located behind the Host Customer’s electric utility meter, and serves either

tenant utility accounts, common area accounts, or a combination of the two, the Applicant will be required

to define the system’s primary use and provide supporting documentation to substantiate this primary

use.

If 51% or greater of the kWh discharged by the system benefit tenant utility accounts, the system’s

primary use will be considered residential, and residential GHG emission standards, operational

requirements and incentive calculations will apply. If 50% or greater of the kWh discharged by the system

benefit common area utility accounts, the system’s primary use will be considered “common area” and the

applicable GHG emission standards, operational requirements, and incentive payment structure will be

determined by the common area meter’s rate schedule. If the common area meter is on a non-residential

rate, non-residential GHG emission standards, operational requirements, and incentive payment structure

will apply. If the common area meter is on a residential rate, residential GHG emission standards,

operational requirements, and incentive payment structure will apply.

If the primary use case of a multifamily project is determined to be residential, all benefiting tenant

accounts will be required to be enrolled in an SGIP-approved residential TOU rate.

3.4 System Owner

The System Owner is the owner of the SGIP incentivized equipment. In the case when a vendor sells a

system to a Host Customer, the Host Customer is the System Owner. In the case of a leased system, the

lessor is the System Owner. The System Owner shall be designated on the Reservation Request Form.

If the System Owner is not the Host Customer and withdraws from the project, the Host Customer will

retain sole rights to the incentive reservation and corresponding incentive reservation number. To

30

preserve such incentive reservation and corresponding reservation number, the Host Customer must

submit revised application documentation

29

to the Program Administrator.

3.5 Applicant

An Applicant is the person or entity that is responsible for completing and submitting the SGIP application

and serves as the main point of contact for the Program Administrator throughout the application process.

Host Customers may act as the Applicant, or they may designate a third party to act as the Applicant on

their behalf. Host Customers may elect to change the Applicant at any time with prior written notice to the

Program Administrator.

3.6 Developer

A Developer, if not an individual homeowner applying for SGIP incentives for a system located on their

own property, is the corporate entity registered and in good standing with the Secretary of State of

California that handles a substantial amount of the project’s development activities.

30

For the purposes of the SGIP, completing a substantial amount of the following project activities qualifies

an entity to assume the role of project Developer:

1. Approaching or communicating with the Host Customer about the project and learning about its

needs and energy profile

2. Developing the specifications for a system based on the customer’s needs and interests

3. Soliciting bids from multiple manufacturers for the specified system

4. Gaining the customer’s commitment to purchase or lease the specified system, usually but not

necessarily by signing a purchase order with a customer or other form of agreement

5. Purchasing the specified system from the manufacturer to fulfill the obligation to provide a system

to the customer

6. Securing permits for the system on behalf of the customer

7. Securing interconnection permission for the system on behalf of the customer

8. Submitting SGIP applications on behalf of the customer

9. Liaising with the Program Administrators on incentive reservations

10. Liaising with the Program Administrators on data reporting requirements

11. Supplying project data to SGIP evaluators

12. Physically constructing the system at the customer’s premises

13. Installing the system at the customer’s premises

The Program Administrators, with approval from the Statewide Working Group, have discretion to

determine whether a participant handles such activities, and whether a participant handles a substantial

29

Application documentation may include: the latest SGIP application form that was submitted (Reservation Request Form, Proof of

Project Milestone Form, Incentive Claim Form) and all preceding supporting documentation submitted.

30

If the Homeowner is handling a substantial amount of the project’s development activities, they may apply to be the Developer

and would not require standing with the Secretary of State.

31

amount of these activities for a given project. If a reassignment of Developer status for a given project

occurs after an SGIP application is submitted but before a confirmed reservation is issued and leads to a

participant retroactively exceeding its Developer Cap for a given incentive step, the project will be

cancelled or a sufficient number of alternate reservation requests for that Developer will need to be

cancelled to bring the Developer under its Developer Cap.

Developer Application Process

SGIP projects must select an approved Developer before the application may be submitted. A list of

approved Developers is available at https://www.selfgenca.com/home/resources. Entities interested in

becoming an approved SGIP Developer can submit a Developer Eligibility Application

(www.selfgenca.com/home/dev_register/)

31

to the Program Administrators, containing the following

information:

32

• If a parent company for the participant exists, the ultimate owner of the parent company, if the

parent company is nested within other parent-child corporate relationships, revelation of the

ultimate owner is required.

• Any ownership interest, including a minority interest, in the Developer held by another Developer

or ultimate owner of another Developer is required.

• The identity of the entity, if reasonably foreseeable, that will execute any of the development

activities not performed by the Developer named in the Developer Eligibility Application

• If the Developer plans to divide project development activities with another entity in different ways

for different projects, the Developer must note that on the application form and submit

supplemental information with the Developer Eligibility Application describing those other ways for

other projects.

• To the extent not described in the section asking for information on execution of project

development activities, a description of relationships with other SGIP participants (including

commercial or financial relationships between Developers that do not share the same majority

ownership) in developing and/or owning any existing projects funded in whole or in part by the

SGIP or reasonably foreseeable future projects that may be funded in whole or in part by the

SGIP is required.

Additionally, if requested by the Program Administrator, Developers may be required to provide the

following documentation:

1. Articles of Incorporation

2. Certificate of Incorporation

31